Each medical institution should be able to use the latest tools to improve nursing and provide the best patient experience. 3D printing provides personalized care for patients through more effective workflow, faster surgery, and better identification and visualization, and provides patients with innovative solutions.

Medical SLA 3D printer features

1. 3D printing can produce small batches of customized components -even only one part of one part at a time -no extra cost, no time or tools.

2. Medical SLA 3D printer can easily produce complex geometric shapes in plastics or metals. Add material manufacturing has performed well in high customized applications

3. All one-piece molding and high accuracy. This can improve design and reduce costs and shorten production time.

4. Eliminate the gap between multiple components, making it easier to disinfect the equipment, and it is difficult to breed bacteria.

5. By using 3D scanning and X-ray to quickly create detailed 3D models, the time and costs of medical professionals are saved.

Medical 3D printer introduces digital manufacturing into the interior, minimizing costs and time, thereby achieving flexible product development and personalized care. You can start from a small scale, add SLA medical printers and capacity with your growth. If you are considering to buy medical SLA 3D printer from reliable manufacturer, please feel free to contact us!

Application: Orthopedic preoperative model, Orthopedic surgery guide, Orthodontics, medical teaching and educational models, therapeutic tools

Strength

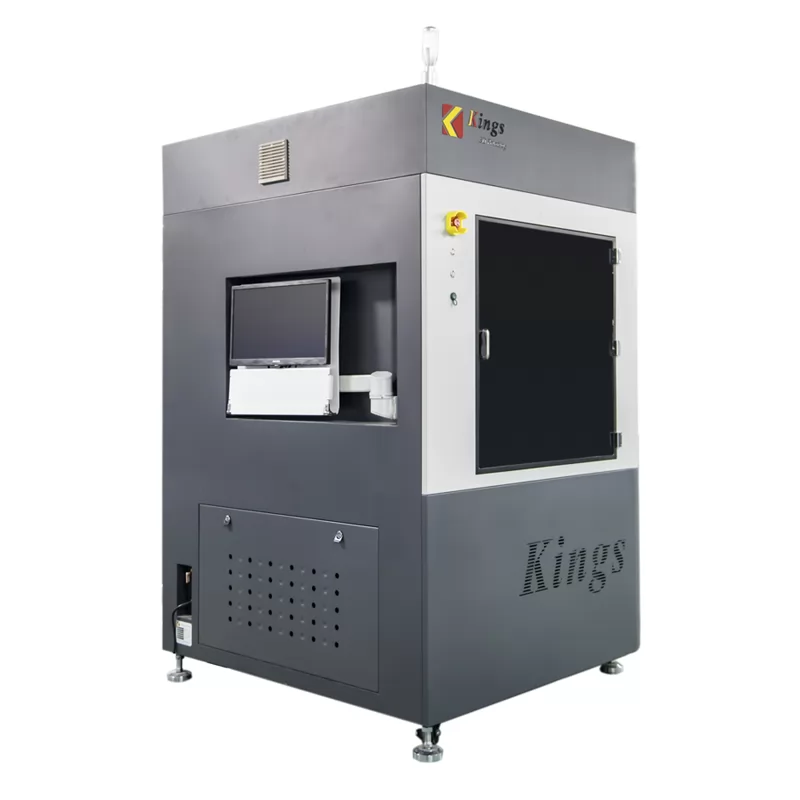

The potential of Kings 600Pro medical 3D printers in health-care is vast. Models can be printed for teaching and educational purposes, as diagnostic aids, for treatment planning, or for therapeutic means etc. Tolerances of Kings 600Pro parts are typically less than 0.05 millimeters, making it an excellent choice when precision is your top priority. And delivering the smoothest surface finish of any additive manufacturing process.

Application Cases of Kings 600Pro in medical field

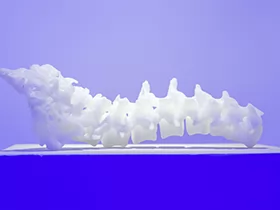

1. Orthopedic preoperative model

3D model is reconstructed according to the patient's CT / MRI data, and a 1:1 physical model help with disease diagnosis, preoperative surgical plan design, and preoperative surgical operation.

2. Orthopedic surgery guide

Kings 600Pro 3D printed Orthopedic models can be used to assist in the preoperative simulation of craniofacial surgery, which effectively helps with the three-dimensional reconstruction of soft tissue morphological structures, and the positioning, moving and rebuilding of complex three-dimensional structures such as skulls, jaws, and sacrum. Common examples include skull models, jaw models, and outer ear models.

3. Orthodontics

High-precision dental model can be made through Kings 600Pro 3D printer, and personalized invisible braces for different patients can be produced accordingly.

4. Teaching and educational models

The models printed by Kings 600Pro SLA 3D printer convey a wealth of information that may be difficult to express in a standard anatomic drawing or a two-dimensional image such as a radiograph or CT/MRI slice. Complex anatomy can be shown to patients and their families by the referring physicians in a very tangible means which is less abstract to non-medically trained individuals than conventional imaging studies.

Models of normal anatomy can be utilized early in medical education similar to conventional skeletons in the anatomy lab and library. The relatively low cost of 3D printed models compared to commercially available models make them a viable option for budget conscious departments.

5. Therapeutic Tools

Orthotics and can be created quickly and inexpensively based on exact patient measurements and requirements. This is particularly useful in patients who are rapidly growing or in disease processes that evolve over time. In areas of the country or world that have limited access to commercial prosthetics and orthotics, a Kings 600Pro medical 3D printer offers otherwise impractical or impossible therapeutic options.

Commonly used 3D printing material in the medical industry

Stainless steel

Stainless steel, disinfection and biological compatibility, commonly used in surgical tools and temporary implants, such as bone screws

Nylon PA-12

Nylon PA-12 has good flexibility and chemical resistance. It is also one of the most printed and most affordable medical -grade materials

PC-ISO

PC-ISO is a biocontinical polycarbonate (PC) engineering thermoplastic plastic for FDM 3D printed. Its surface treatment quality is lower than the nylon PA-12, which is mainly used for surgical guidelines, prototypes and molds.

ABS M30i

ABS M30i is another heating plastic plastic for biocompatibility engineering for FDM. FDM printing is very suitable for functional prototypes, shapes in shape, and final use components.

Titanium

Titanium is the most popular medical implant material. Replacement joints, pacemakers, skull boards, dental implants, etc. are usually made of titanium. Titanium is very strong, light weight, and corrosion resistance.

Cobalt chromium

Cobalt chromium alloy has corrosion resistance and excellent biocompatibility. Compared with titanium, it has higher strength and hardness, and is widely used in joint replacement of frequent use of knee joints, hip and shoulder joints.

TPU (thermoplastic polyurethane)

TPU is a flexible rubber material with heat resistance and can be exposed to the skin for a long time with the skin for 30 days. Poor components, respiratory masks, medical tubes and sealing pieces are usually made of TPU.

Looking for high quality medical SLA 3D printer for sale, please contact us for detailed information!