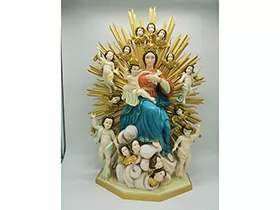

Application: sculpture prototype, statue prototype

Traditional ways

After making 3D model drawing of a sculpture or statue, CNC machine is used to make the prototype first. Then use the models to produce silicon or plaster mold and mold to make prototype or finished products.

Challenge

·Many waste and dust

·The model is cut in many pieces due to irregular shape and complicated structure

·Changing tools frequently with different parts

·Complex production process, especially for RFP products making

Kings 3D solutions

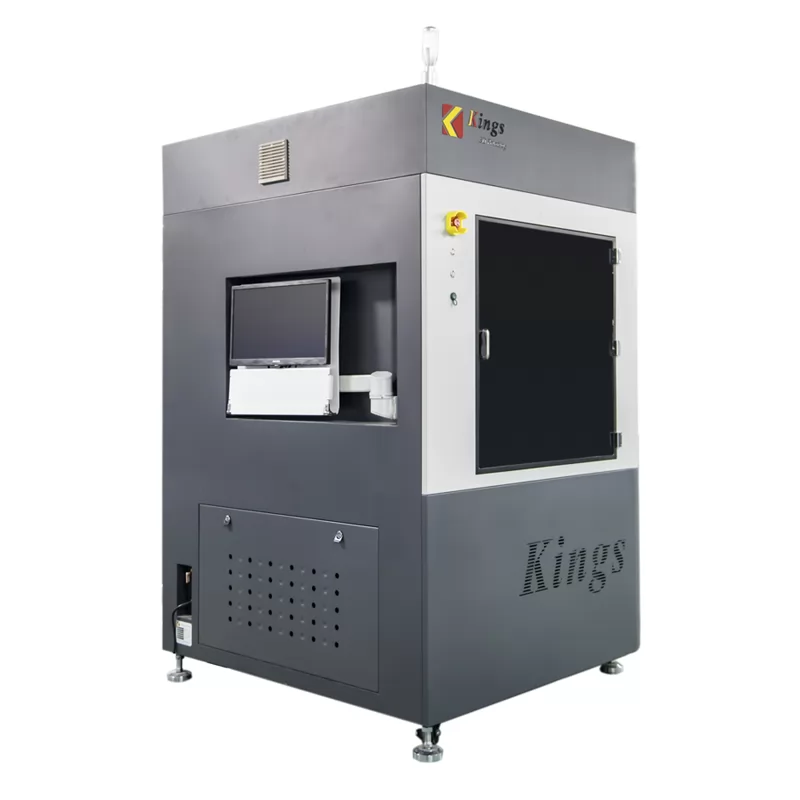

Kings large format SLA 3D printer Kings 800Pro is a reliable and sturdy resin 3D printer designed for large scale printing, especially suitable for big sculptures and statues. Large statue SLA 3D printer can improve the production efficiency and the quality of the finished products.

Large Statue SLA 3D Printer Benefit

·Time-saving: Kings 800Pro SLA 3D printer prints sophisticated sculpture fast as any other regular models

·Smooth surface finish: Layer thickness min.0.05mm

·Less cutting and gluing work: large printing size 800*800*500mm

·User-friendly: no tool change, clear and simple work-flow

·Large prints, print large and exquisite details

·Low material waste

Art sculpture production

The traditional method of making art is too slow, it will limit your work as an artist. Using 3D printing, you can create complex artworks. The only limit is your imagination.

Use the industrial 3D printer to make art exhibits, especially those irregularly shaped exhibits. You can print the model as a whole, or it can be split into multiple parts, saving time and reducing the risk of transportation damage. If you are looking for high quality large statue SLA 3D printer for sale, welcome to contact us for detailed information!

Printing steps

Step 1: Check the sculpture model and divide according to the construction volume of our printer.

Step 2: Arrange parts in the software and add necessary support. Then print them with SLA durable resin 3D. The minimum layer is 0.05mm.

Step 3: After the printing is completed, use the IPA to flush the model and solidify it with UV. Cut off all the support, and then polish it with sandpaper.

Step 4: Use white paint and transparent acrylic coverage parts to prevent yellowing. Use strong glue to assemble them together.

Recommended 3D Printing Material: UV Resin KS408, UV Resin KS608