Recently, the Traffic Management Bureau of the Ministry of Public Security has deployed the “One Helmet and One Belt” security guard operation nationwide. It is advocated that motorcycle and electric bicycle riders wear helmets correctly. The market demand for helmets has increased significantly, and market prices have skyrocketed. The factory is also working overtime and mass production. Many helmet factories use 3D printing technology to design and model in order to meet the needs of the majority of users. Thereby creating more safe and personalized helmets.

3D printing helmet technology may not be well understood by everyone. Let's take a look at the production process of 3D printing helmet:

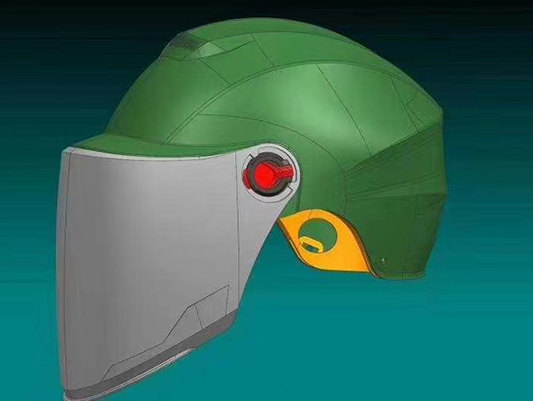

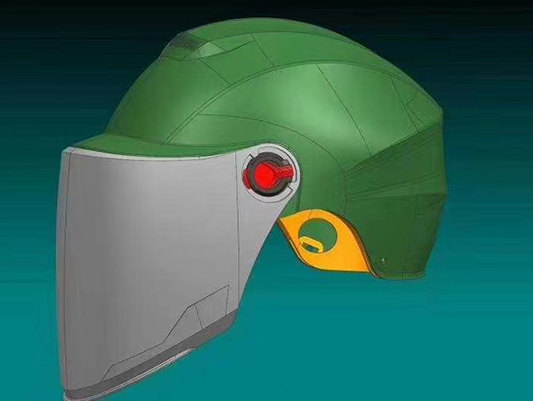

1. First design a helmet model file, slice and add support.

2. Copy the sliced helmet model image file to the SD card and start printing.

3. Remove the model after printing, remove the support, and polish the uneven places. According to the need, the helmet model can also be colored, and some other accessories can be added.

After reading the production process of the 3D printing helmet, I believe you have some understanding of this 3D printing technology, then let me explain to you what benefits the 3D printing helmet has.

Benefit 1:

With the development of the times, young friends are increasingly pursuing personalized customization, and customized helmets are also loved by many users. If the manufacturer wants to open a mold to make a custom helmet, the cost is high, and 3D printing technology can solve this problem. According to the designed helmet model, it is printed with high-strength ABS material. According to the color you like, you can print out a very personal 3D printed helmet.

Benefit 2: 3D printed helmets can reduce the cost of mold opening for helmet manufacturers

All products require mold opening from design to production. Models designed by designers need to be verified by mold opening before mass production. In the meantime, if the designed model fails to produce after the mold is opened, it needs to be modified to open the mold again. We all know that the cost of mold opening is quite high, which is a big expense for manufacturers. However, the 3D printer can print the solid model according to the model file. The solid model can be displayed three-dimensionally in front of the designer, and the cost is very low, so the 3D printed helmet can reduce the mold opening cost of the helmet manufacturer.

At present, with the strengthening of national traffic safety regulations, the market demand for 3D printed helmets will continue to increase. It is understood that there are already many helmet manufacturers consulting some 3D printed helmet solutions. I also hope that in the future we can produce better 3D printing products to serve the helmet manufacturing market.