When traveling to Chongqing, you must go to Jiefangbei. To do 3D printing, you must find the Qiuping model. Especially in the automotive industry, this company is almost the best choice for the entire Chongqing city.

In just a few years, Qiuping model has been rapidly emerging as a leader in the hand model industry. Many automobile companies represented by Changan Automobile and Ford Motor are their cooperative customers. What did they do? Let us find out.

Stand Out from The Competition

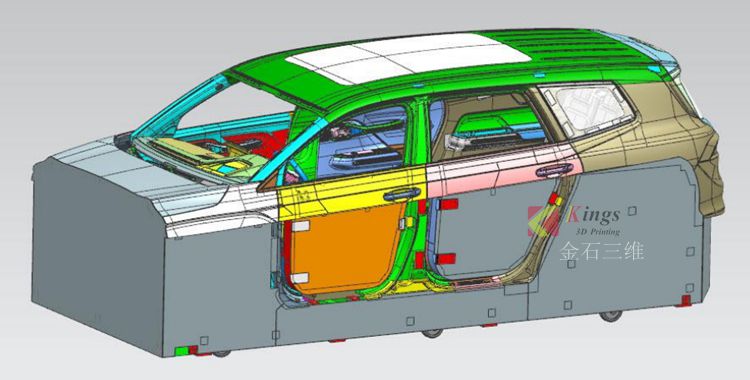

When the market is full of competitors, we must locate the vacancies by positioning, so that the breakthrough Qiuping model is positioned at the beginning: The heavy-duty hand model of the automobile and aerospace industry and the precise positioning of the rapid mold manufacturing determine the subsequent layout. The processing equipment purchased by the Qiuping model is a large-scale equipment to meet the needs of the hand-made model production of the automotive industry.

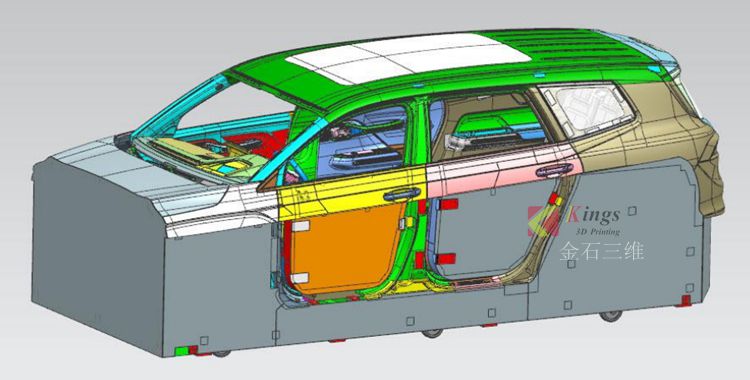

3D printing auto parts

5 Times Faster with Kings Large Format SLA 3D Printers

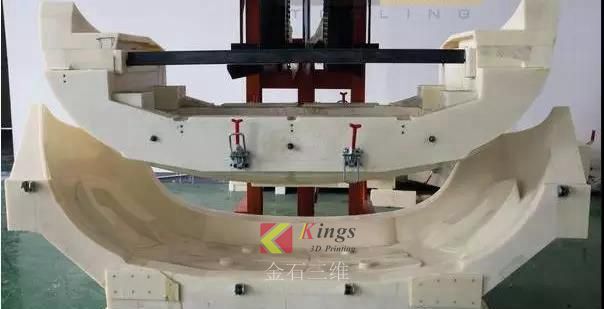

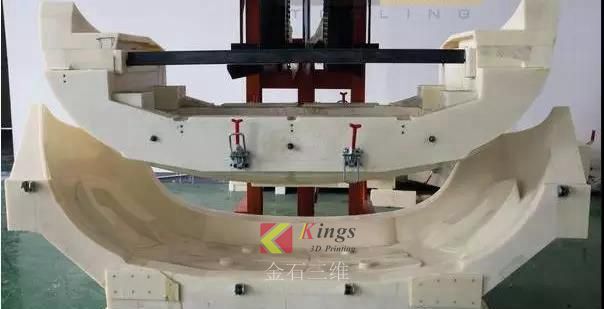

In 2016, Qiuping model signed a purchase agreement with Shenzhen Jinshi in line with the goal of improving market competitiveness. It has purchased 12 large-scale industrial-grade 3D printers of KINGS brand. 3D printing can print large-size products, such as automobiles. Grilles, bumpers, dashboards, etc., reduce errors due to multiple stitching. At the same time, the rapid prototyping capability of the photo-curing 3D printer has also increased the production efficiency of the Qiuping model by more than five times.

Zheng , manager of Qiuping, said: “The vehicle verification model that was cooperating last month is an example. If you use the traditional method, it may take a month to complete and use the Kings 3D printing equipment. The RP part of the vehicle is completed in one week, and the RP is guaranteed. Good quality".

3D printing car model

Cost Reduction by 7 times

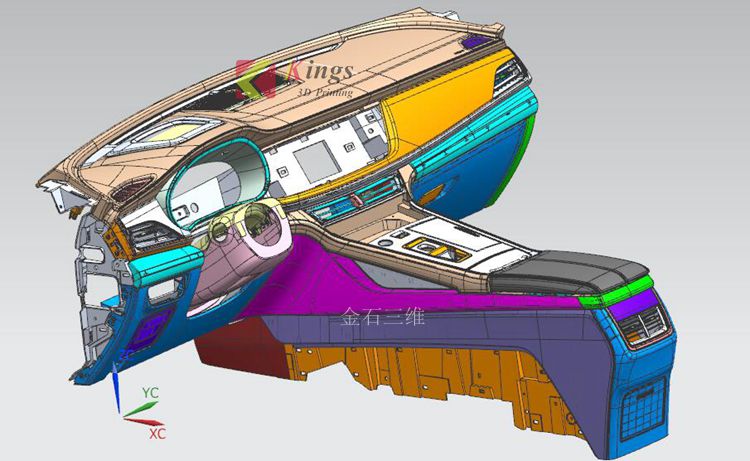

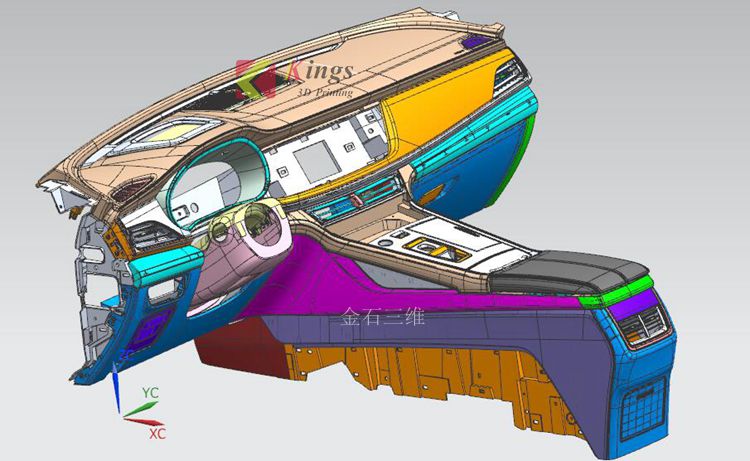

The small batch of finished samples is an important part of the prototype trial stage. The quality of the prototype is especially important for the perfect tooling design and prototype test, so it must meet the short production cycle and high dimensional accuracy. The Qiuping model combines 3D printing with vacuum forming (low pressure infusion) to form a rapid mold manufacturing method.

Taking the instrument panel as an example, a simple comparison is made between the rapid mold making process and the soft steel mold making process. As shown in the above figure, the silicone rubber-epoxy quick mold manufacturing process has obvious advantages in terms of mold making cycle and cost. Significantly reduce the rapid sample development cycle and reduce costs.

Finished product made by 3D printing + vacuum forming (low pressure infusion) process

According to the interview with the Qiuping model by the Kings 3D Marketing Department, Mr. Qiu Ping said: "The company has both large CNC and large 3D printing equipment and other equipment in terms of hardware equipment. We have a team of design and vehicle model development in technology. The professional production capacity of mold and low pressure perfusion can be said to be the most professional automobile hand model and small batch manufacturer in Chongqing. Many automobile companies represented by Changan Automobile are our strategic cooperation customers.

3D printing car hand model made by Qiuping

You might want to know more about:

1. KINGS1700 Pro SLA 3D Printer

2. KINGS 800Pro Industrial SLA 3D Printer

3. Kings SLA Resins