As 2024 comes to a close, we reflect on an exciting and transformative year at Kings 3D. Throughout the year, we’ve continued to push the boundaries of 3D printing technology, introduced new and improved products, and built stronger relationships with our clients across various industries. Here’s a look back at the key highlights from this year and the advancements that have shaped Kings 3D’s success.

Keywords: Kings 3D, 2024 highlights, 3D printing advancements, innovation, product improvements, client relationships, 3D printing industry success, year-end review

SLA: Advancing Customization and Stability

Our SLA printers have made significant strides in 2024 with the introduction of upgraded, self-developed control software. The new software enhances user experience by offering improved stability and a greater range of customization options. This advancement allows our clients to achieve even higher precision in their 3D printed parts, all while maintaining the reliability that has become synonymous with our SLA technology.

(Kings SLA workshop)

SLM: The Launch of the Kings M480

We are excited to announce the launch of the Kings M480, an upgraded version of the popular Kings M450E. The M480 features a larger build volume of 480 x 320 x 300 mm, providing customers with greater flexibility and the ability to print larger, more complex parts. This new model delivers increased stability and enhanced precision in metal 3D printing, making it an ideal choice for industries that require high-quality metal parts with fine details.

(Kings SLM M480E 3D Printer)

Compared to its predecessor, the M480 offers improved thermal management and faster print speeds, resulting in a more efficient production process and reduced operating costs. It maintains the high reliability and accuracy of the M450E while delivering superior performance at a more competitive price. The Kings M480 is designed to meet the growing demands of aerospace, automotive, medical, and other industries where precision and performance are critical.

You can also visit the official website of our metal 3D printer subsidiary, Laseradd, for more information about our metal 3D printers!

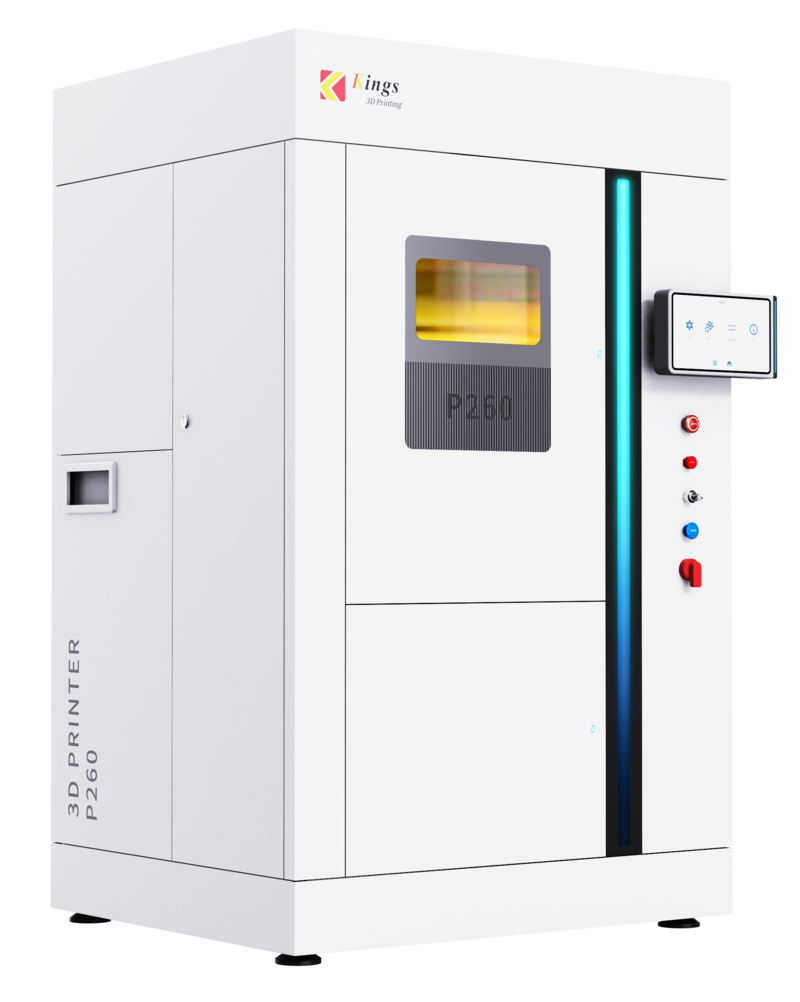

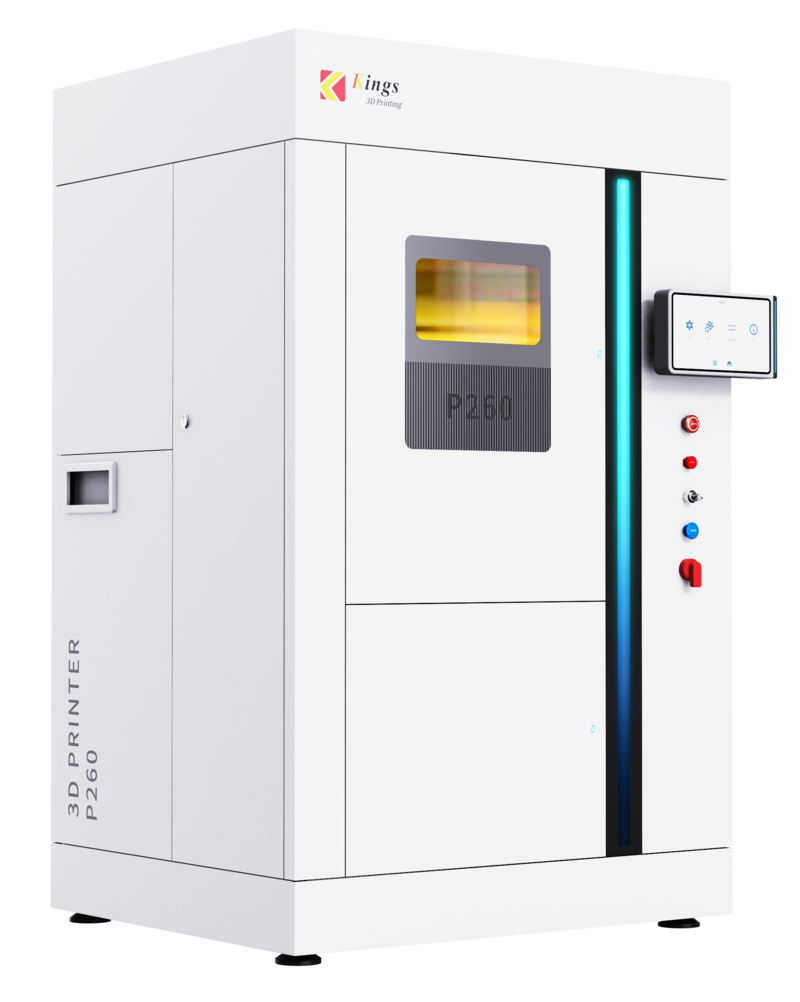

SLS: Newly Launched P260 - Meeting the Demands of Small-Scale Production

In response to the growing demand for small-batch production, we introduced the P260 machine, designed specifically for small-scale SLS production. This machine joins our P440, which continues to serve industries requiring precision and efficiency. Together, these machines provide a complete solution for customers looking for high-quality, low-volume production of intricate parts.

(Kings SLS P260 3D Printer)

FGF: Optimizing for Large-Scale Applications

Our FGF printers have undergone continuous optimization in 2024 to meet the evolving needs of various industries. Especially notable is their success in large-scale applications, such as furniture, sculptures, and outdoor crafts. These printers have proven to be adaptable, delivering excellent performance for oversized and complex designs that require robust material handling and precision.

(Bathtubs printed by Kings FGF 2435 3D printers)

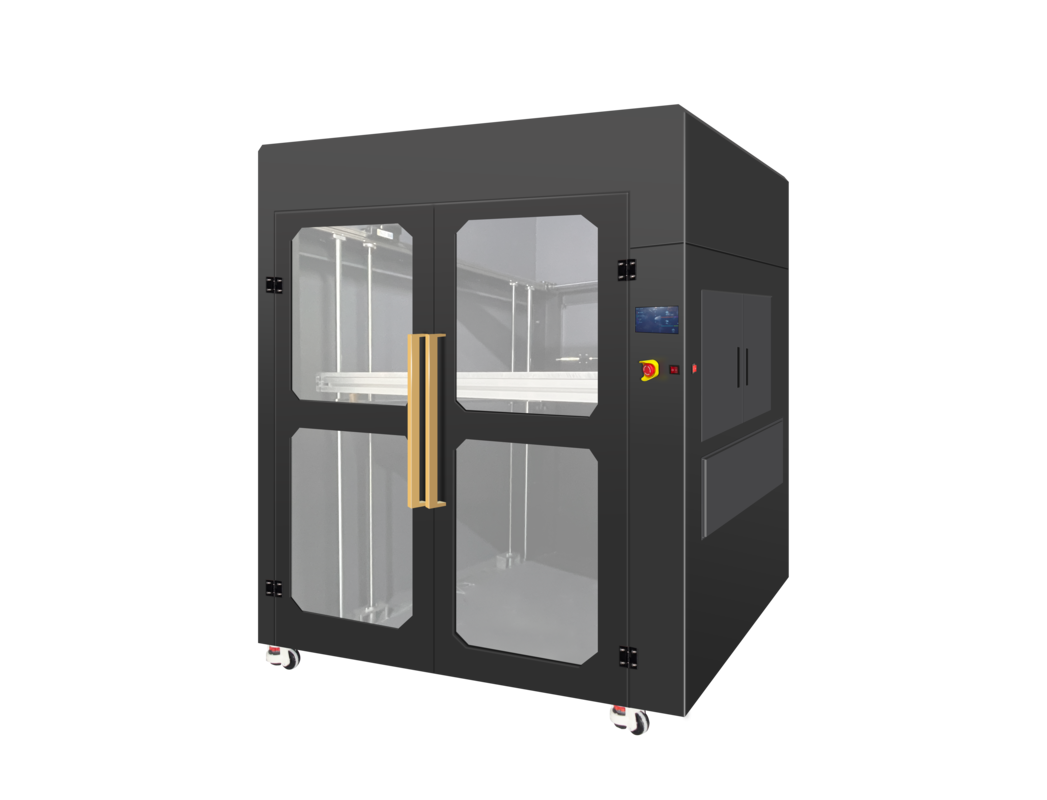

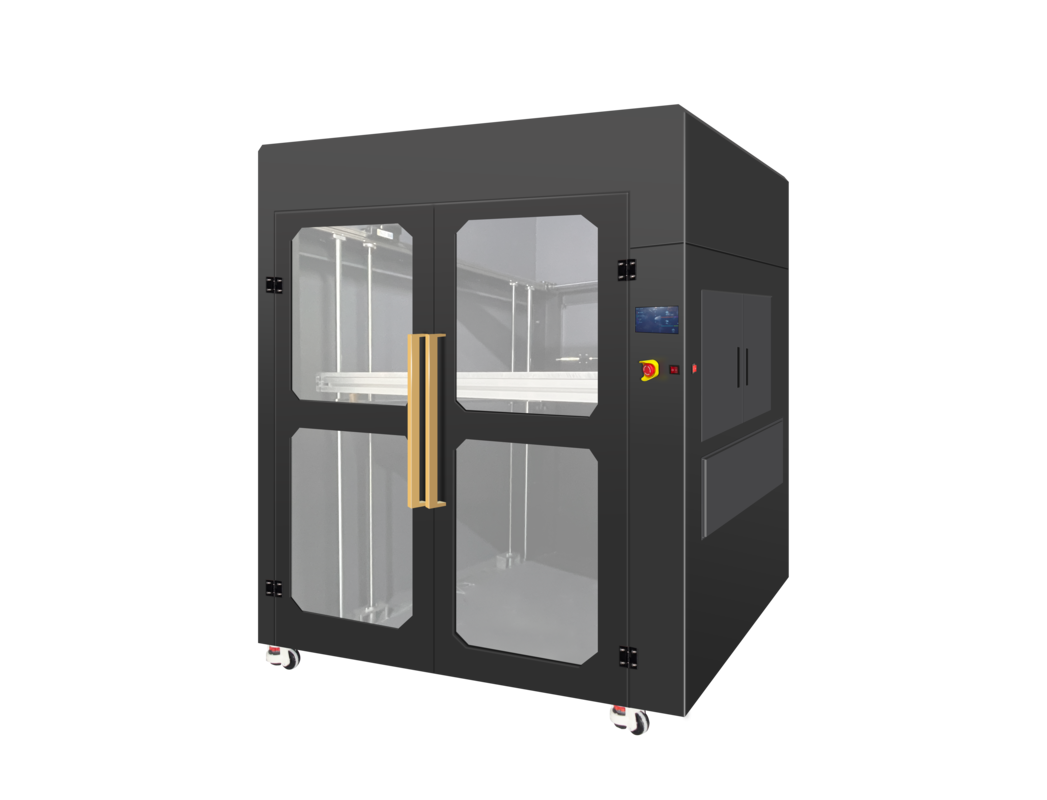

FDM: High-Performance and Cost-Effectiveness

Kings' FDM printers, including the FDM 1000 and FDM 5060, stand out for their exceptional cost-performance ratio. In 2024, we've focused on enhancing these printers for medium to large-scale part production, ensuring our customers can achieve the highest quality at an affordable cost. These printers are perfect for businesses looking for reliability, efficiency, and quality without the high costs typically associated with industrial-scale 3D printing.

(Kings FDM 1000 3D Printer)

(Kings FDM 5060 3D Printer)

Additive Material: Elevating 3D Printing Materials

This year, our sub-brand Additive Material has been key in providing a diverse range of high-quality 3D printing materials, including resins, powders, and pellets. Our materials have become an excellent alternative to many leading brands, offering exceptional quality and cost-effectiveness for various applications. Whether for SLA, SLS, or FDM printing, Kings' materials continue to set new standards for performance and reliability.

In 2024, we also launched our dedicated material sales website, Additive Material. We warmly welcome you to visit and follow us there, where you can find more specialized and extensive information about King's 3D printing materials.

(Kings 3D Printing Materials - Resin)

Applications Across Industries

One of the most exciting aspects of 2024 has been seeing our printers' capabilities applied across diverse industries. From automotive to aerospace, architecture to advertising, our technology continues to support breakthroughs in design and production.

Notably, our printers have excelled in the footwear, dental, and rapid prototyping sectors, enabling companies to innovate faster and more efficiently.

Looking Ahead

As we move into 2025, Kings 3D remains committed to delivering cutting-edge 3D printing solutions that drive innovation across industries. We are continuously improving our products and expanding our capabilities to meet the ever-changing demands of our clients. The success of 2024 has been built on your trust and collaboration, and we look forward to working together to create even more groundbreaking solutions in the coming year.

2024 has truly been a year of growth and transformation for Kings 3D. From advancements in hardware and software to the launch of new products and materials, we've seen great progress in pushing the limits of 3D printing technology. We are excited about what the future holds and are grateful for the continued support of our clients and partners.

Here's to even greater achievements in 2025!