Recently, the journal Additive Manufacturing Frontiers (AMF), supervised by the China Association for Science and Technology and hosted by the Chinese Mechanical Engineering Society, released a special issue titled "30 Years of Development of Additive Manufacturing in China," organized by Executive Editor-in-Chief Professor Li Dichen. The special issue features high-quality papers from over ten representative teams in China’s additive manufacturing field, showcasing the development, major research achievements, and future trends of China's additive manufacturing technology over the past 30 years. Among them, the team of Professor Yang Yongqiang, Chief Scientist of Kings 3D and Professor at the South China University of Technology, published a paper titled Frontiers in Laser Additive Manufacturing Technology, exploring the current challenges and future directions of laser additive manufacturing. Professor Yang is the first author of the paper, with Professors Wang Di and Song Changhui as corresponding authors.

Cite the Paper: Yongqiang Yang, Renwu Jiang, Changjun Han, Jiaqi Chen, Haoran Li, Yan Wang, Jinrong Tang, Heng Zhou, Weinan Hu, Boyuan Zheng, Zixin Liu, Changhui Song, Di Wang. Frontiers in Laser Additive Manufacturing Technology. Additive Manufacturing Frontiers, 2024, 200160.

Click to View Full Text: https://www.sciencedirect.com/science/article/pii/S2950431724000509

The article is mainly divided into three major sections:

1. Current Status of Laser Additive Manufacturing:

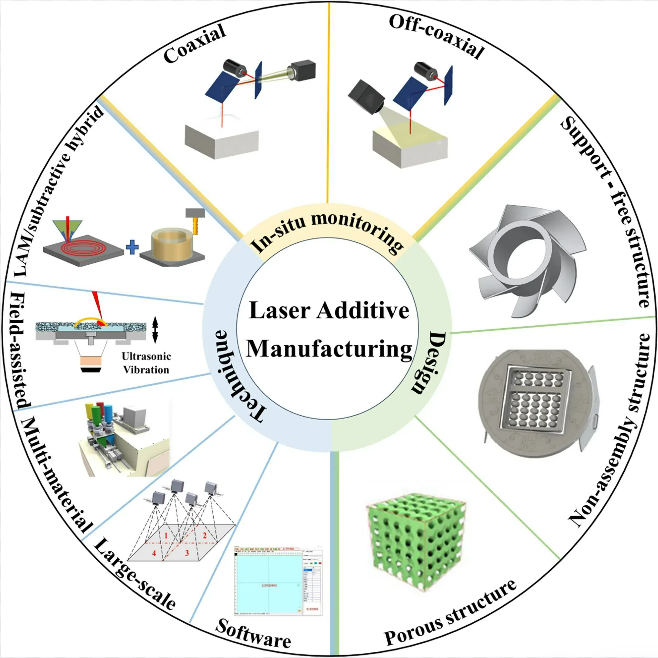

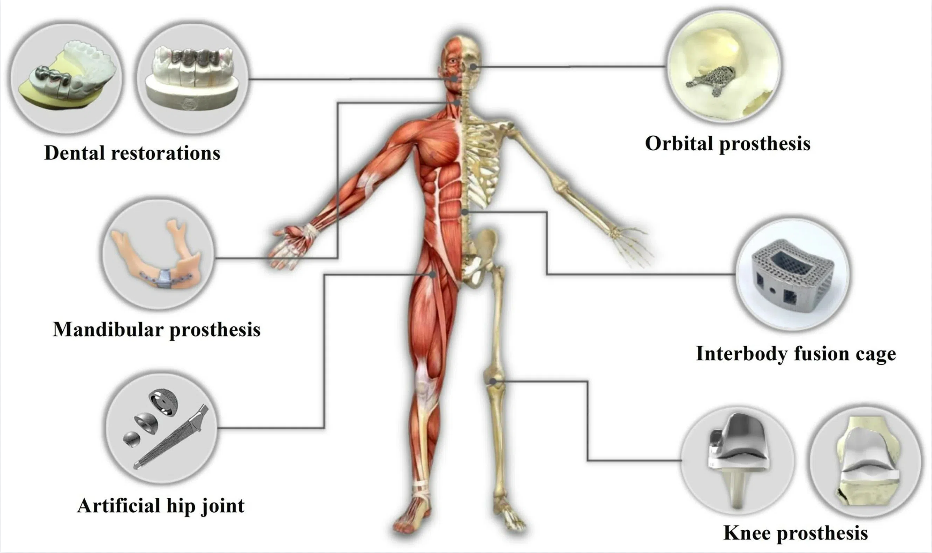

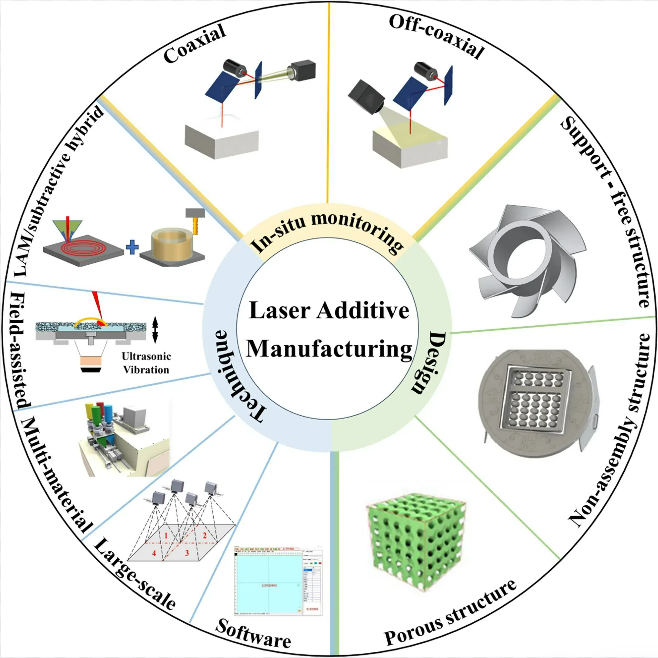

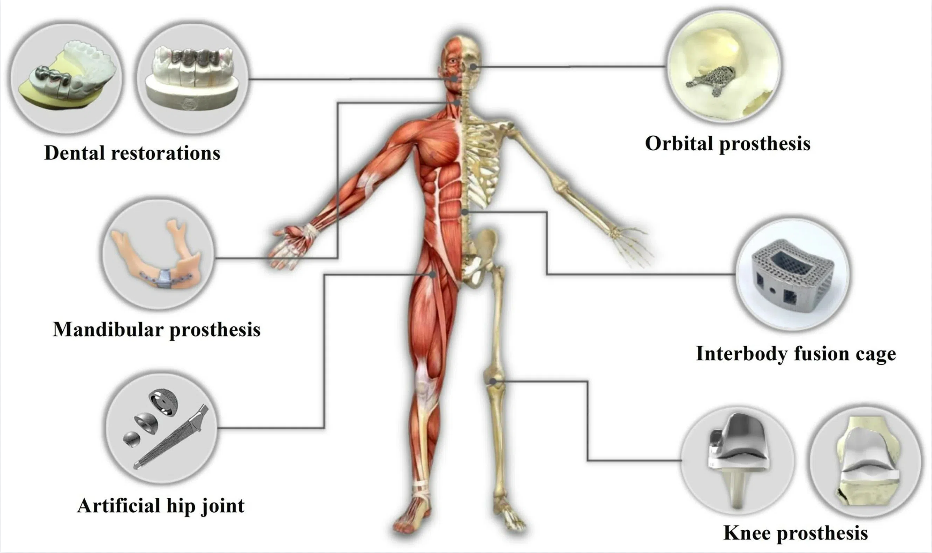

Laser additive manufacturing is one of the mainstream metal additive manufacturing technologies today, primarily including Laser Selective Melting (LSM) and Laser Directed Energy Deposition (LDED) technologies. Due to the small laser spot size, high energy density, and small heat-affected zone, this technology can ensure the formation of high-density, high-performance, and intricate complex parts. It has been widely applied in aerospace, industrial molds, and biomedical fields.

2. Challenges in Laser Additive Manufacturing Technology:

Currently, laser additive manufacturing technology still faces the following prominent issues:

Limited Forming Size of Laser-Selective Melting Equipment: The size of parts that can be formed using laser-selective melting equipment is still restricted.

Low Control Precision and Immaturity in 3D Heterogeneous Material Forming: There is low precision in controlling the forming of 3D heterogeneous materials, and the technology is not yet mature.

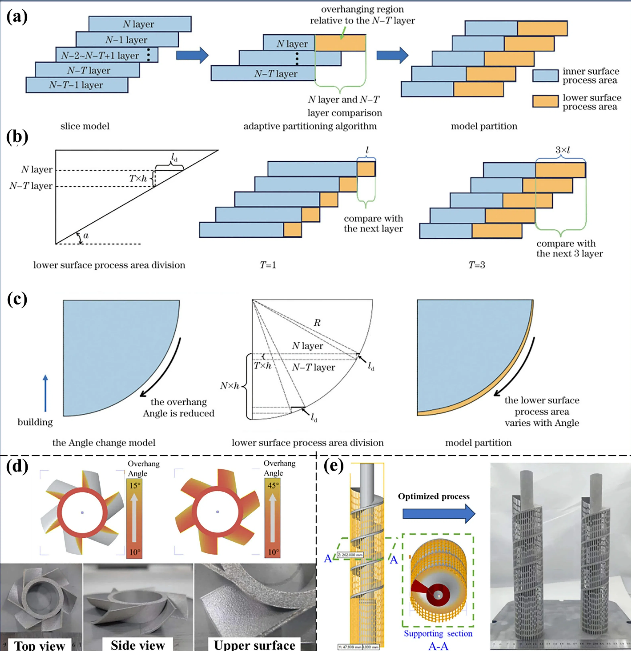

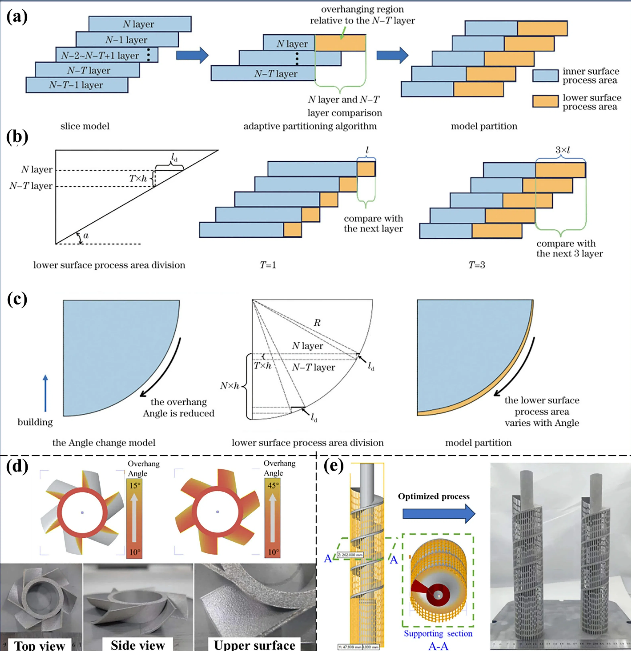

Need for Improved Surface Accuracy of Laser Additive Manufacturing Parts: The surface accuracy of parts produced by laser additive manufacturing still needs further enhancement.

Problems with Single Laser Energy Field Parts: Parts produced with a single laser energy field exhibit issues such as high stress, difficulties in defect elimination, and uneven microstructure.

Need for Improved Consistency, Stability, and Reproducibility: There is an urgent need to improve the consistency of forming performance, process stability, and reproducibility of the technology.

3. Potential Future Development Directions for Laser Additive Manufacturing:

The paper outlines potential future development directions for laser additive manufacturing technology:

From Single Laser to Multi-Wavelength/Type/Number Lasers: Evolve from using a single laser to incorporating multi-wavelength (combining red, blue, and green light), multi-type (combining continuous lasers with picosecond and femtosecond lasers), and multi-laser systems to achieve large-scale, high-efficiency, and high-precision additive manufacturing.

From Low Efficiency, Low Connection Quality Multi-Material Additive Manufacturing to High Efficiency, High Strength Multi-Material Additive Manufacturing: Advance from low efficiency and poor connection quality in multi-material additive manufacturing to high efficiency and high strength. This can be achieved by improving existing powder spreading methods and designing interface connection structures, resulting in high-efficiency, high-strength multi-material manufacturing with minimal powder cross-contamination.

From Online Monitoring to Online Control: Transition from online monitoring to online control by establishing an effective evaluation system for monitoring signals such as sound, light, heat, and magnetism, and their correlation with print quality. This will provide key criteria for achieving online control.

Development of Customized Software Solutions: Create tailored software solutions to address path planning and other issues in complex process forming.

About Professor Yang Yongqiang's Team:

Yang Yongqiang (first author) is the Chief Scientist at Kings 3D, Director of the Kings Additive Manufacturing Research Institute, and a Professor at the South China University of Technology. He is an Executive Director of the Additive Manufacturing Branch and Director of the Bio-Manufacturing Branch of the Chinese Mechanical Engineering Society, President of the Guangdong Additive Manufacturing Association, and Vice Chairman of the Guangdong-Hong Kong-Macau Greater Bay Area Laser and Additive Manufacturing Industry Technology Innovation Alliance. He has made significant contributions to additive manufacturing and laser processing, developing the Dimetal series of 3D printers. He has published over 300 papers, authored 8 books, and holds over 360 patents, including 65 granted inventions. He has received 4 provincial and ministerial awards and is a frequent ESI Highly Cited Researcher.

Wang Di (corresponding author) is a Research Scientist at Kings Additive Manufacturing Research Institute and a Professor at South China University of Technology. He specializes in metal additive manufacturing, focusing on laser selective melting equipment, process control, and print quality. He has led 5 National Natural Science Foundation projects and has published over 100 papers. Wang holds 3 PCT patents and over 30 invention patents, has edited 4 books, and his work has earned multiple awards, including the Guangdong Science and Technology Progress Award and the Guangxi Technical Invention Award. He has also contributed to the development of numerous national and industry standards.

Song Changhui (corresponding author) is a Research Scientist at Kings Additive Manufacturing Research Institute and a Professor at the South China University of Technology. He is a distinguished high-level talent in Guangdong Province, specializing in new methods and equipment for laser additive manufacturing and integrated applications of high-adaptability materials. He has led 5 national projects and 8 provincial projects and published 46 SCI papers in journals like Int. J. Mach. Tool. Manu. and Int. J. Extre. Manu., and holds 66 invention patents. He has edited 4 books and received awards including the Guangdong Science and Technology Progress Award and the Beijing Technical Invention Award. His students have also won the "Internet+" National Gold Award.

For more information, feel free to contact us here!