What Is the Advantages of SLA 3D Printing Technology?

By: Kings 3D Gary Wu

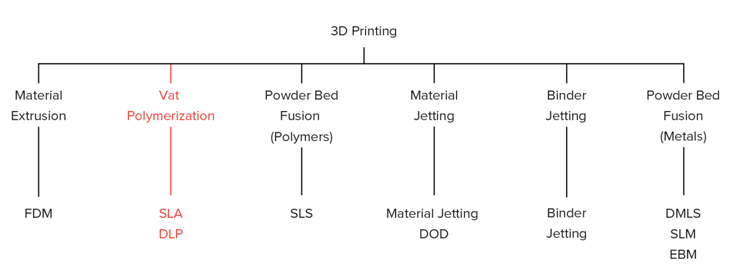

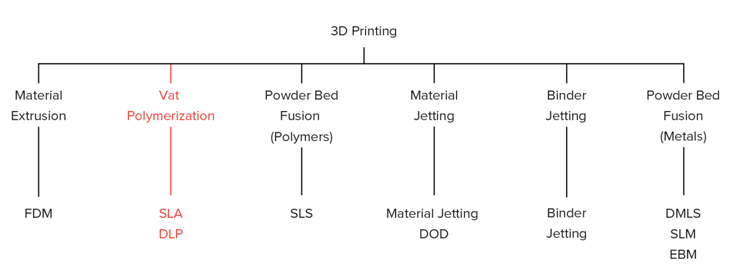

Stereolithography (SLA) is an additive manufacturing process that belongs to the Vat Photopolymerization family. In SLA, an object is created by selectively curing a polymer resin layer-by-layer using an ultraviolet (UV) laser beam. The materials used in SLA are photosensitive polymers that come in a liquid form.

SLA is famous for being the first 3D Printing technology: its inventor patented the technology back in 1986. If parts of very high accuracy or smooth surface finish are needed, SLA is the most cost-effective 3D printing technology available. Best results are achieved when the designer takes advantage of the benefits and limitations of the manufacturing process.

SLA technology is extremely versatile and it can be used when precision is the overall priority and where form, fit and assembly are critical. The tolerances on an SLA part are typically less than 0.05 mm, and this technology offers the smoothest surface finish of any additive manufacturing process. Considering the level of quality SLA can achieve, it’s particularly useful for creating highly precise 3D printed casting patterns from small to very large scale, quickly and inexpensively.

KINGS SLA 3D Printers (printing size ranges from 300*300*350mm up to 1700*800*600mm) offer high throughput, unmatched part resolution and accuracy, and a wide range of print materials. No other additive manufacturing process addresses a wider range of applications, including the most demanding rapid manufacturing applications for highly accurate and durable prototypes of all shapes. When an SLA printed part is completed, it is then cleaned in a solvent solution to remove wet resin remaining on the part surface. Afterward, the part is put in a UV oven to cure it, completing the resin printing process.

In SLA systems, most print parameters are fixed by the manufacturer and cannot be changed. The only inputs are the layer height and part orientation (the latter determines support location).The typical layer height in SLA ranges between 25 and 250 microns. Lower layer heights capture curved geometries more accurately but increase the build time (and cost) and the probability of a failed print. A layer height of 100 microns is suitable for most common applications.

In summary, here are the advantages of stereolithography(SLA):

High precision, fine detail: due to the great thinness of each layer applied in stereolithography (0.05 to 0.25 mm) and the fine laser beam, it is possible to obtain prototypes with a very realistic finish and complex geometric shapes.

Quality of the part: despite the use of substitution materials (resin), parts made with stereolithography have good functional surface quality. SLA allows manufacturers to save time on highly precise parts, especially when you require a number of functional prototypes or a quick single casting pattern

Smooth finish: In stereolithography, the resulting parts have a smooth finish, with the option to choose between a number of resins for different renderings, which makes them easier to polish, paint and finish if necessary, and ideal for wind tunnel testing and similar applications.

From the smallest to the largest: with stereolithography, it is possible to create small parts with high definition, as well as larger parts up to two meters in size, while maintaining high precision. With KINGS large-size 3D printer, you can even print 1: 1 automobile bumpers, grilles, dashboards and other parts. This effectively reduces the errors and waste of labor costs caused by splicing, and also improves the development efficiency of automotive products by more than 5 times.

Price and lead time: By choosing the stereolithography method, you can obtain a part in about two days, because the 3D files are sufficient to launch a printing. On the other hand, the cost is reasonable, because it is not necessary to create a mold, as stereolithography works by adding material.

For more information, pls click: www.kings3dprinter.com