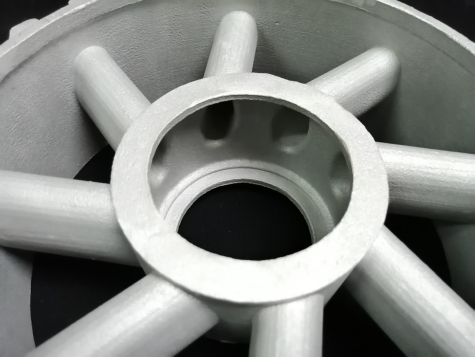

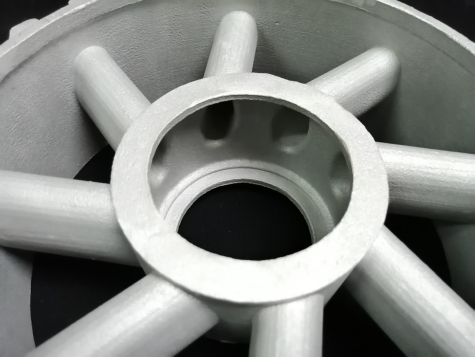

SLA printing is a beast in the investment casting and foundry industry. Known for its high precision and speed, SLA printing is transforming manufacturing processes. Our unique resin material, specifically designed for SLA printing, can replace traditional wax patterns, significantly reducing manual carving costs and mold expenses while drastically shortening mold production time. 3D printing can quickly produce molds and complex structures with intricate textures and patterns.

Advantages of SLA printing with KS168C

1. Reduction in Manual Carving Costs

Traditional wax pattern creation is time-consuming and costly. Our resin material, used with SLA printing, allows for high-precision mold printing, reducing labor costs.

2. Shortened Mold Production Time

Conventional mold production is lengthy. With digital design and rapid prototyping, SLA printing produces complex molds in hours, cutting production time significantly.

3. High Precision and Complex Structures

SLA printing easily creates intricate structures and detailed textures, offering designers greater flexibility and enabling complex, refined casting products.

Conclusion

SLA printing technology in the rapid casting industry enhances efficiency, reduces costs, and improves product quality. Our special resin material and SLA printers address traditional casting pain points and open new possibilities for the industry's future, promoting a more efficient, precise, and intelligent future.