The Kings SLS R&D team was initially established in 2012 and has been committed to research in the field of SLS 3D printing. With more than ten years of experience accumulation, the R&D team has independently developed the control software & scanning algorithms, making the equipment a qualitative breakthrough in molding efficiency and quality.

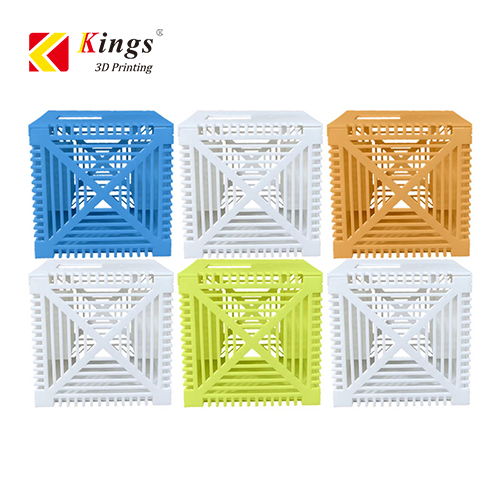

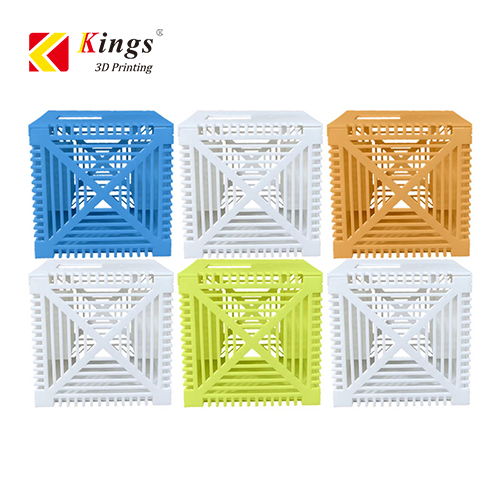

After using the printer for almost one year domestically, Kings 3D officially released the 3D printing equipment---Kings SLS nylon P440 in the global market. The printing size, precision, and efficiency are industry-leading, and it is equipped with a two-way intelligent powder spreading with double scrapers, and products of about 5KG can be printed within 24 hours.

Features:

Ø Large printing size and high molding efficiency

The size of the molding cylinder is 440*440mm (XY).

The continuously optimized temperature control scheme and scanning path scheme improve the molding efficiency.

It will be upgraded for free of charge for life.

Ø The reuse rate of consumables is nearly 100%

The original revival technology of PA powder makes the powder utilization rate close to 100%;

Ensuring the high surface quality and great mechanical properties of the parts.

Ø The equipment utilization rate is nearly 100%

A:Through the optimization of the anti-oxidation of consumables, after the printing is completed, the cylinder can be taken to cool down,

and at the same time, the printing operation of the next cylinder can be continued when the equipment is still at high temperature,

which can effectively reduce the cooling and warm-up time and reduce energy consumption

B: It adopts an external powder cylinder to realize automatic powder feeding and powder replenishment at any time during printing.

Ø Two-way intelligent powder spreading with double scrapers

The dual-scraper two-way intelligent powder supply system offers extremely fine details for the industrial-quality parts,

which also decreases the amount of powder overflow, thus improving the material use rate.

Application:

Ø Electronic and electrical structural parts

Ø Medical aids and equipment

Ø Education

Ø Architecture model

Ø Automotive

Ø Aerospace

Ø Prototype model

Ø Animation

Material:

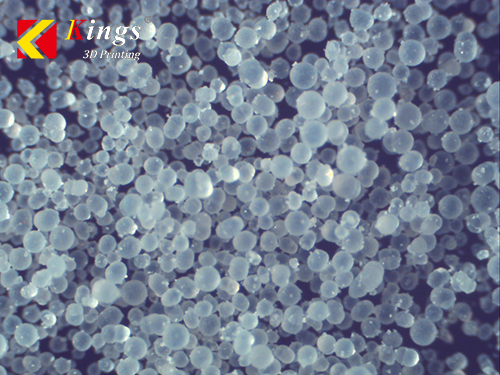

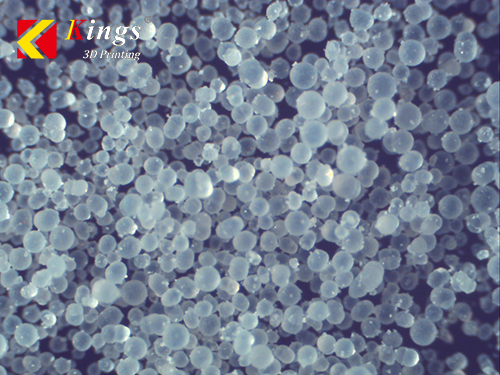

Material model: PA12 nylon powder (GFPA12)

Features:

A. High color stability in repeated use.

B. The particle size D50 of the powder material is about 50 microns, and the distribution is narrow and uniform. The powder has high sphericity and high fluidity. It can still maintain excellent mechanical properties, and the surface finish of molded parts is high even when the powder reuse rate is close to 100%.

(Microscopic morphology of PA12 spherical powder)

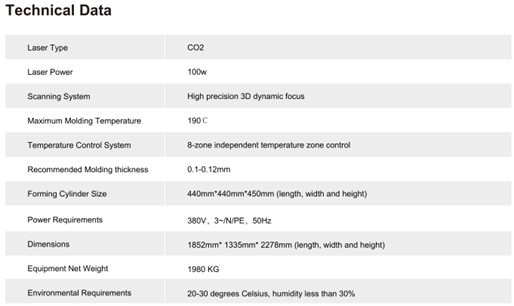

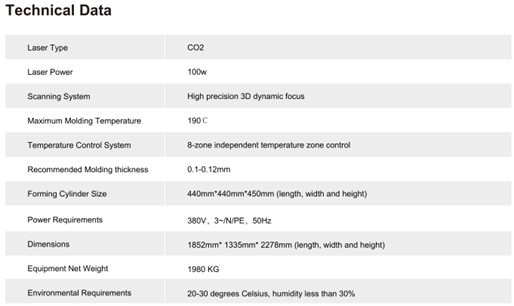

The main technical parameter:

Mechanical property | Value | Unite | Test standard |

Tensile Modulus | 1600 | MPa | ISO 527 |

Tensile Strength | 46 | MPa | ISO 527 |

Strain At break | 20 | % | ISO 527 |

Charpy Impact Strength | 38 | KJ/m2 | ISO 179 |

Charpy Notched Impact Strength | 7.5 | KJ/m2 | ISO 179 |

Flexural Modulus | 1400 | MPa | ISO 178 |

Flexural Strength | 50 | MPa | ISO 178 |

Thermal Properties | Value | Unite | Test Standard |

Powder Melting Temperature (10℃/min) | 187 | ℃ | ISO 11357 |

Vicat Softening Temperature (50℃/h 50N) | 100 | ℃ | ISO 306 |

Other properties | Value | Unite | Test Standard |

Density(laser-sintered) | 0.94 | g/cm3 | Own method |

Density(Powder) | 0.52 | g/cm3 | Own method |

Particle Size(D50) | 60 | μm | Laser Diffraction |

The release of the P440 nylon 3D printer marks the overall layout of Kings 3D in the field of SLS nylon 3D printing. As an enterprise with a complete industrial chain in the 3D printing industry, Kings 3D currently has a comprehensive product line covering SLA, SLM, SLS, DLP, FGF, and other fields, and will continue to promote the expansion and coverage of 3D printing business in more subdivided fields in the future.

Author: Gary / Lili Lu / Seazon/Yami