Metal 3D printing, a game-changer in various industries, is steadily making inroads into the footwear sector, offering a unique blend of design freedom, performance enhancement, and sustainability. While plastic remains the dominant material in shoe production, metal 3D printing opens up a new realm of possibilities with its distinct properties and applications. Let's delve into the diverse material landscape of metal 3D printing in footwear:

1. Titanium: The Pinnacle of Performance:

Lightweight Strength: Titanium's low density and high strength-to-weight ratio make it ideal for high-performance footwear, particularly athletic shoes. It significantly reduces the weight of the shoe without compromising its structural integrity, enhancing speed and agility.

Biocompatibility: Titanium's biocompatibility is a boon for orthopedic footwear, allowing for the creation of custom-designed implants and prosthetics that integrate seamlessly with the body.

Corrosion Resistance: Titanium's exceptional corrosion resistance makes it suitable for shoes designed for extreme conditions, such as outdoor sports or marine applications.

2. Stainless Steel: Durability and Versatility:

Robust Structure: Stainless steel's high tensile strength and durability make it ideal for creating robust shoe components like cleats, heel plates, and midsoles, capable of withstanding high impact and wear.

Aesthetic Appeal: Stainless steel's polished finish adds a sophisticated touch to high-end footwear, offering a unique aesthetic that complements the durability.

Customization: Metal 3D printing allows for complex and intricate designs, enabling manufacturers to create customized stainless steel components that meet specific design requirements.

3. Aluminum: Lightweight and Cost-Effective:

Lightweight Performance: Aluminum's lightweight nature makes it ideal for reducing the overall weight of footwear, contributing to improved comfort and athletic performance.

Cost-Effectiveness: Aluminum's affordability compared to titanium and stainless steel makes it a viable option for mass production, particularly for sports and outdoor footwear.

Design Flexibility: 3D printing's design flexibility allows for the creation of complex and intricate aluminum components, optimizing weight distribution and enhancing shoe performance.

4. Nickel-Based Alloys: Tailored Properties for Specific Needs:

High-Temperature Resistance: Nickel-based alloys like Inconel exhibit exceptional high-temperature resistance, making them suitable for specialized footwear designed for extreme environments.

Corrosion Resistance: Nickel-based alloys also boast excellent corrosion resistance, making them ideal for shoes exposed to harsh conditions, such as marine environments or industrial settings.

Customized Properties: Different nickel-based alloys offer a spectrum of properties, allowing manufacturers to tailor the material to specific requirements, such as increased strength, durability, or heat resistance.

5. Beyond the Basic Materials:

Composite Materials: Metal 3D printing enables the creation of composite structures, combining metals with polymers or ceramics to achieve specific properties, like enhanced stiffness, flexibility, or insulation.

Functional Gradients: Metal 3D printing allows for the creation of functionally graded structures with varying material properties within a single component, optimizing performance for specific applications.

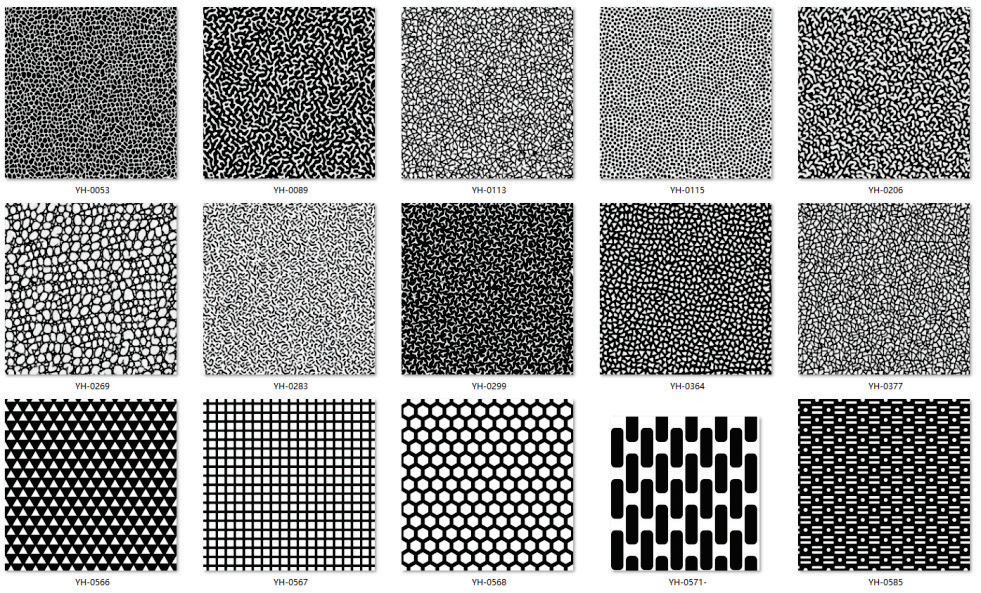

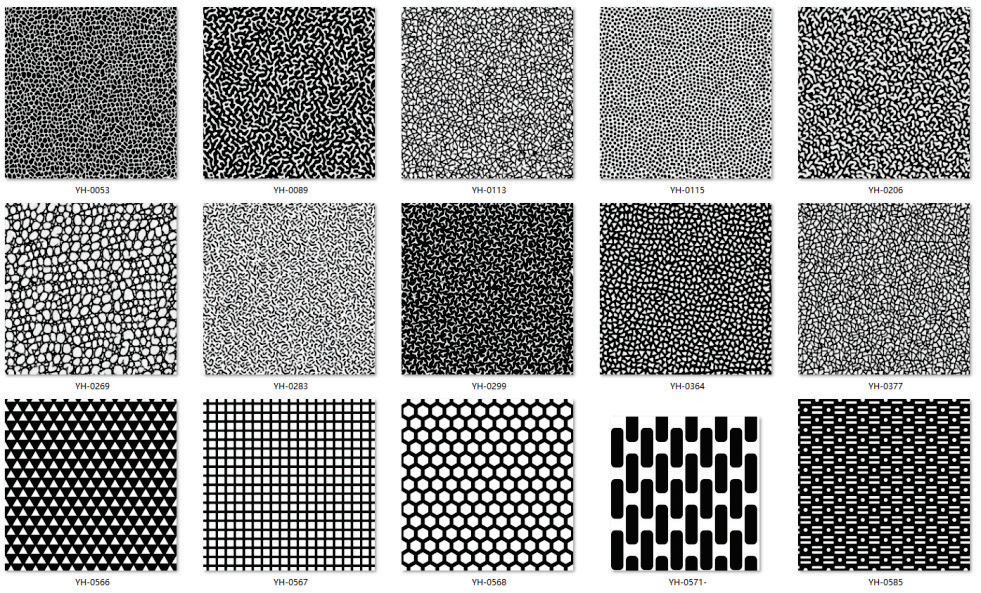

Surface Treatments: Metal 3D printing offers flexibility in surface treatment, allowing for various finishes, coatings, and textures to enhance aesthetics, durability, or performance characteristics.

Conclusion:

Metal 3D printing in footwear opens up a world of possibilities, offering unprecedented design freedom, enhanced performance, and sustainable manufacturing practices. The diverse spectrum of materials, coupled with the unique capabilities of 3D printing, allows designers and manufacturers to create footwear that is lighter, stronger, more durable, and tailored to specific needs. As the technology continues to evolve, the future of footwear will undoubtedly be shaped by the innovative applications of metal 3D printing.

If you are interested in more of our metal 3D printing or its application in shoe industry, feel free to contact us here!

Author: Ruby/ Christine