The application of metal 3D printing technology in the field of medical implants is gradually becoming a revolution that leads to the future of healthcare. The limitations of traditional manufacturing methods in terms of complexity, precision, and customization have driven the increasing demand for more advanced technologies in the medical field. Metal 3D printing technology, with its unique advantages, perfectly meets these needs and is transforming the design and manufacturing of medical implants.

Keywords: Metal 3D Printing, Medical Implants, 3D Printed Implants, Additive Manufacturing, Healthcare Innovation, Custom Implants, Precision 3D Printing, Complex 3D Structures, Biocompatible Materials, 3D Printing Technology

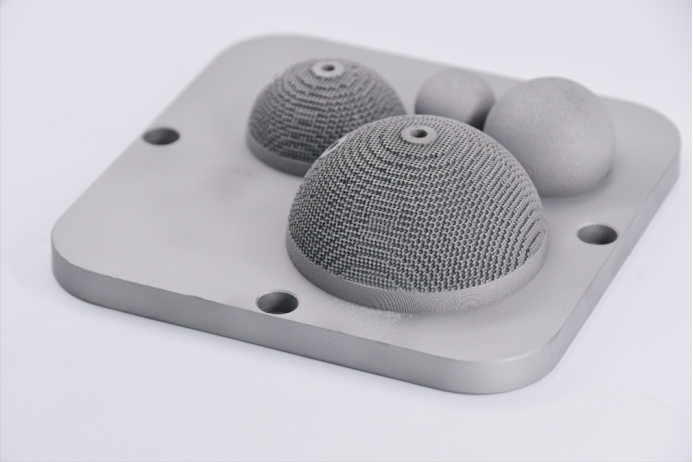

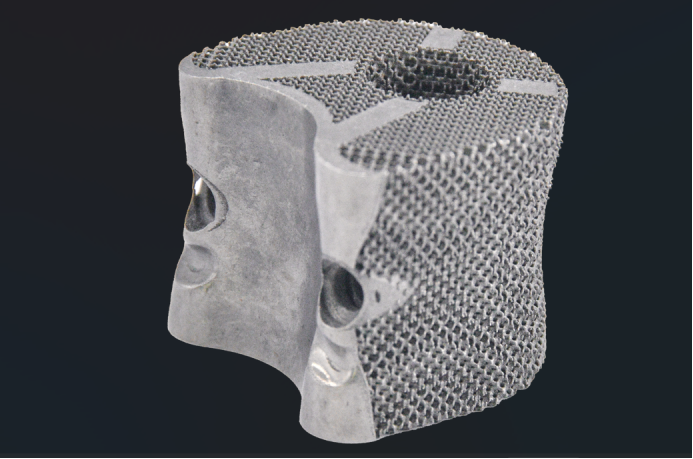

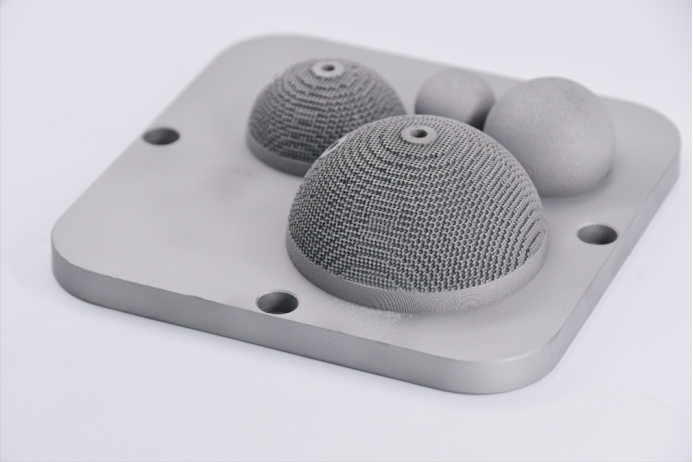

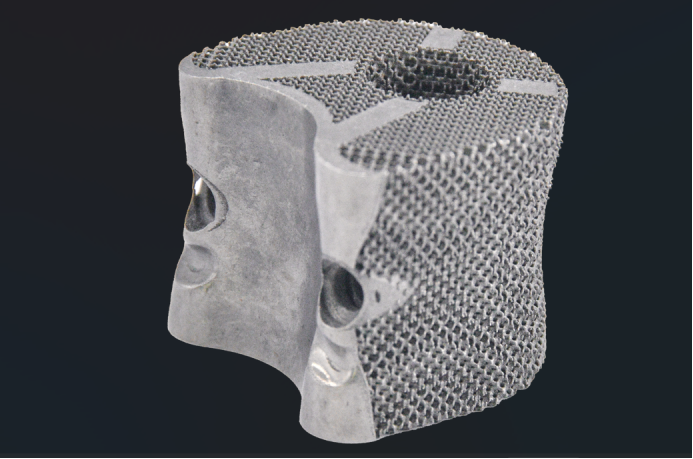

First and foremost, customization is one of the most significant advantages of metal 3D printing in the medical field. Every patient has different anatomical structures and physiological conditions, and traditional implants, which are often designed with standardization in mind, struggle to fully meet individual patient needs. Metal 3D printing, however, can precisely print implants that match the patient’s bone structure based on their CT or MRI scans. Whether it’s hip joints and knee joints in orthopedic surgery or dental implants in the dental field, metal 3D printing technology enables truly "tailor-made" solutions, significantly improving the precision and success rate of surgeries.

In terms of material selection, metal 3D printing technology also showcases its unique advantages. Materials such as titanium alloys and cobalt-chromium alloys, known for their excellent biocompatibility and mechanical properties, are ideal choices for 3D-printed medical implants. Titanium alloys not only possess superior corrosion resistance, allowing them to remain stable within the human body for extended periods, but also offer high strength and low density, making implants both lightweight and durable. This ensures that patients can quickly resume normal activities post-implantation. Cobalt-chromium alloys, with their exceptional wear resistance and biocompatibility, are widely used in dental restorations, maintaining long-term stability in the complex oral environment.

As technology continues to advance, the prospects for the application of metal 3D printing in the field of medical implants are becoming increasingly broad. In the future, we can anticipate the integration of more innovative materials and designs into 3D printing technology, further improving the performance and safety of medical implants. At the same time, with the gradual reduction in production costs and the widespread adoption of the technology, metal 3D printing will no longer be limited to high-end medical institutions but will gradually enter more hospitals and clinics, providing services to a broader range of patients.

In conclusion, metal 3D printing technology is fundamentally changing the way medical implants are manufactured, providing strong technical support for the development of personalized medicine. In the future, this technology will continue to drive progress in the medical industry, offering patients safer and more efficient treatment options, ultimately improving their quality of life.

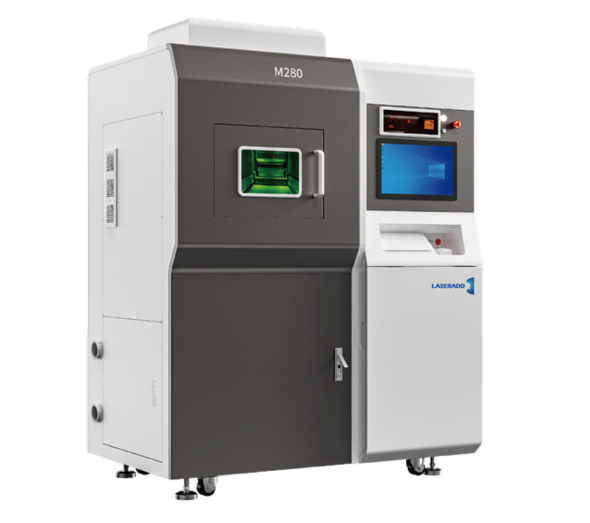

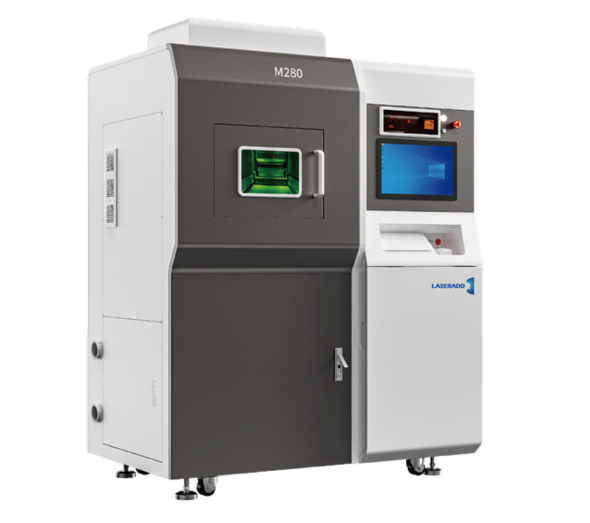

(Kings SLM 3D Printer M280)

If you have any questions or more insights, feel free to contact us here!

Author: Tiffany / Christine