What is SLA 3D printing doing for the fashion industry?

With efficiency and high accuracy, SLA 3D printing is widely used in the fashion industry, which mainly focuses on jewelry.

SLA technology is the first 3D printing technology that achieves commercial production. It utilizes ultraviolet light to rapidly shape photosensitive polymers. The production process of SLA technology can be roughly summarized as follows:

Under the irradiation of ultraviolet light, the photosensitive resin is cured by the shape of the slice.

Then the platform will rise, and the photosensitive resin will be cured again on the original cured thin layer, therefore the cured thin layer is finally formed layer by layer.

As for the excess resin, it can be recycled and used again.

The material selection of 3D-printed jewelry is also a vital factor. These wearable products frequently contact with the wearer's skin closely, which means the material selection needs to be durable, sweat-resistant, UV-resistant, stain-resistant, and skin-friendly.

As for wearable products, skin contact will be important in product use. The wearer's skin contact might influence the appearance of the product, making it fade or the surface treatment fails. Environmental wear and tear can not be avoided, but a good finish can reduce surface breakouts and protect it from color changes due to UV rays, stains, or other marks.

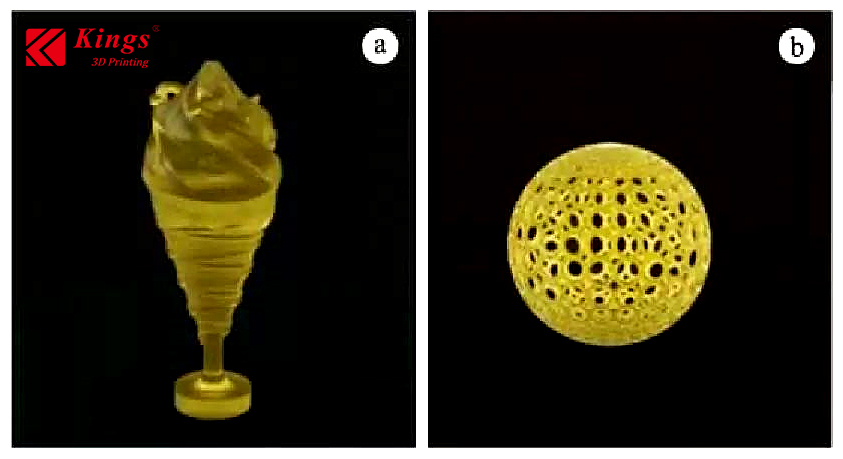

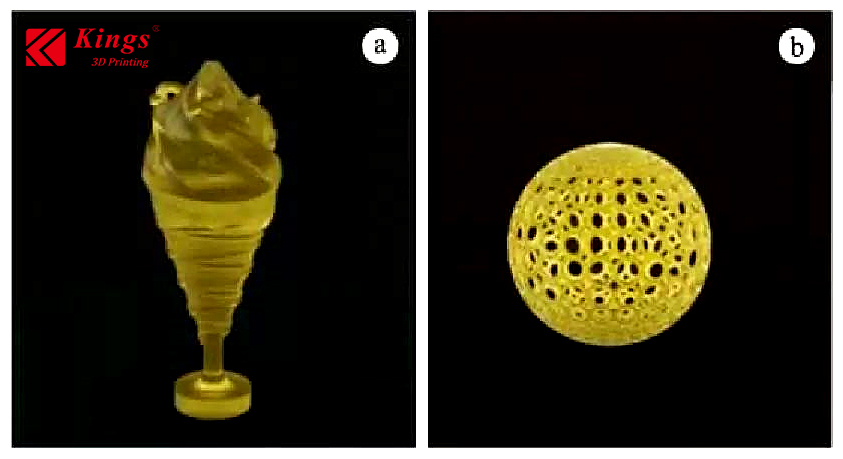

The first set of jewelry is an ice cream pendant and a hollow ball pendant. The 3D printing of the ice cream pendant vividly showcases the flow of the ice cream part and the mechanism of the cone part. Meanwhile, the fine chocolate beans on the ice cream are also printed in great detail.

The ring in the upper left corner can be used for stringing, and it is easy to wear. As the bottom of the model is flat, therefore it does not need to add support when modeling, which reduces the waste of printing resin. The hollow ball pendant has a relatively fine hollow structure. That reflects the advantages of 3D printing in precision casting. The printing of the whole hollow structure is very delicate, and the pendant of the small ball is small and suitable to wear.

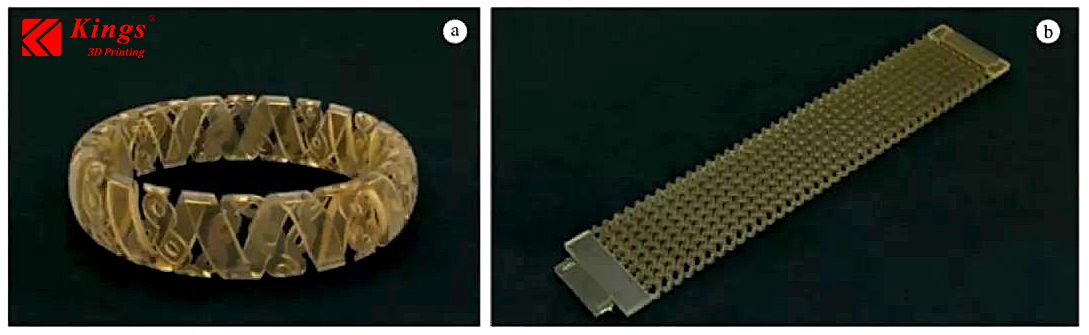

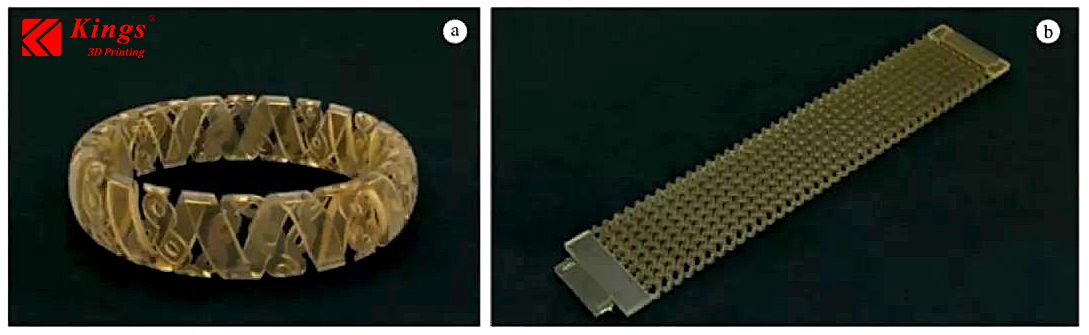

The second group of jewelry is a ring bracelet and a bar bracelet. The whole bracelet consists of two intertwined DNA chains. The two parts are separated from each other and are structures that can be moved.

3D printing directly integrates the two parts of the movable structure needing no post-processing, reflecting the advantages of 3D printing. Bar bracelets with perforated holes can be inserted into a strap to tighten the wrist after the ends are closed.

The printing accuracy of light-curing forming is very high (each layer thickness is only 0.02 mm), and the details of printed jewelry are lifelike, making it accurately express the surface finish and smooth effect of jewelry. Meanwhile, stereolithography technology has the advantage of surface forming. That is to form multiple samples simultaneously, improve printing efficiency, and shorten printing time.

For more details, please visit our website: http://kings3dprinter.com.

Contributor: Blythe/Yami