Because additive manufacturing processes build objects by adding material layer by layer, they offer a number of unique advantages over traditional subtractive and molding manufacturing processes. High-quality 3d printer manufacturers tell you about their benefits.

High Speed

Using traditional manufacturing processes, it can take weeks or months to receive a part. 3D printing machines can transform CAD models into physical parts in a matter of hours, producing parts and assemblies from one-off concept models to functional prototypes and even small batches for testing. This allows designers and engineers to develop ideas faster and helps companies bring products to market faster.

Low Cost

With 3D printing, there is no need for the expensive tooling and setup associated with injection molding or machining; the same equipment can be used to create parts with different geometries, from prototyping to production. As 3D printing becomes increasingly capable of producing functional end-use parts, it can complement or replace traditional manufacturing methods for a growing number of low- to medium-volume applications.

Customization

From shoes to clothes and bicycles, we are surrounded by limited, uniform-sized products as companies strive to standardize products to make them more economical to manufacture. With 3D printing, each product can be tailored to the customer with only changes to the digital design, without the cost of additional tooling. This shift first began to take hold in industries that require made-to-measure customization, such as medicine and dentistry, but as 3D printing becomes more affordable, it is increasingly being used to mass customize consumer products.

Design freedom

3D printing allows for the creation of complex shapes and parts, such as overhangs, microchannels and organic shapes, that would be costly or impossible to produce using traditional manufacturing methods. This offers the opportunity to combine components into fewer individual parts to reduce weight, lighten weak joints and shorten assembly times, unlocking new possibilities for design and engineering.

Reduce risk

Product development is an iterative process that requires multiple rounds of testing, evaluation and improvement. Finding and fixing design flaws early can help companies avoid costly modifications and tool changes. With 3D printing, engineers can thoroughly test prototypes that look and perform like the final product, reducing the risk of usability and manufacturability issues before going into production.

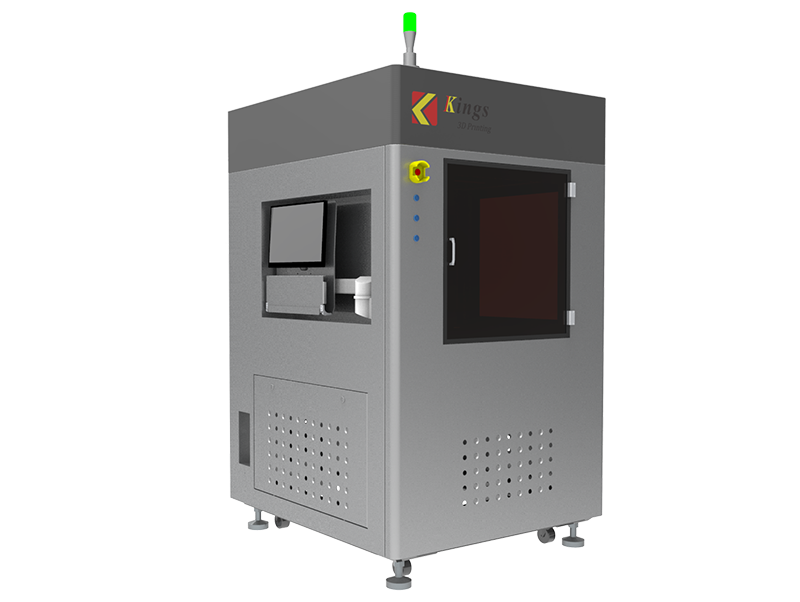

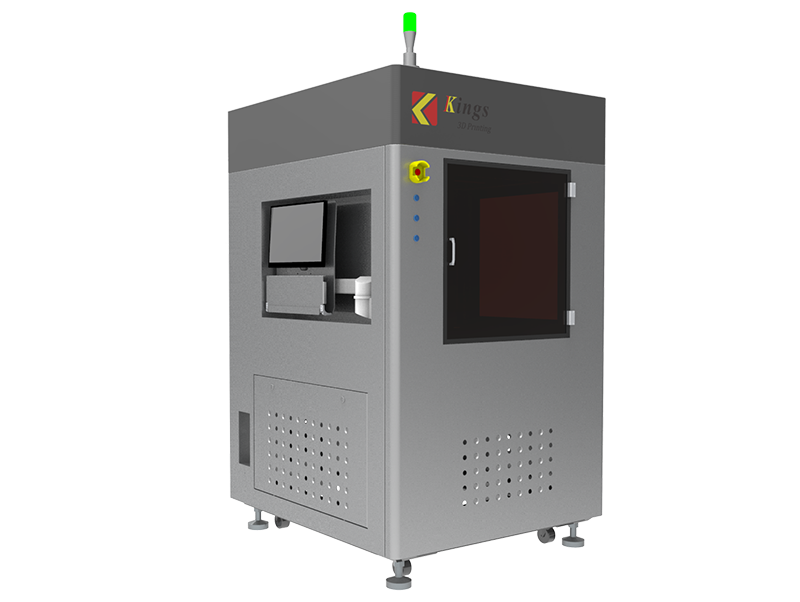

3D printers can be used in many industries. For more knowledge, come to Shenzhen Kings 3D Printing Technology and we will answer your questions.