As a variant of FDM 3D printing, FGF is still not familiar to many people. How exactly does FGF print?

FGF is a fused granular fabrication technology using granular pellets as materials, not filaments. However, to use pellets as raw materials requires a special type of extruder than the one found on FDM printers.

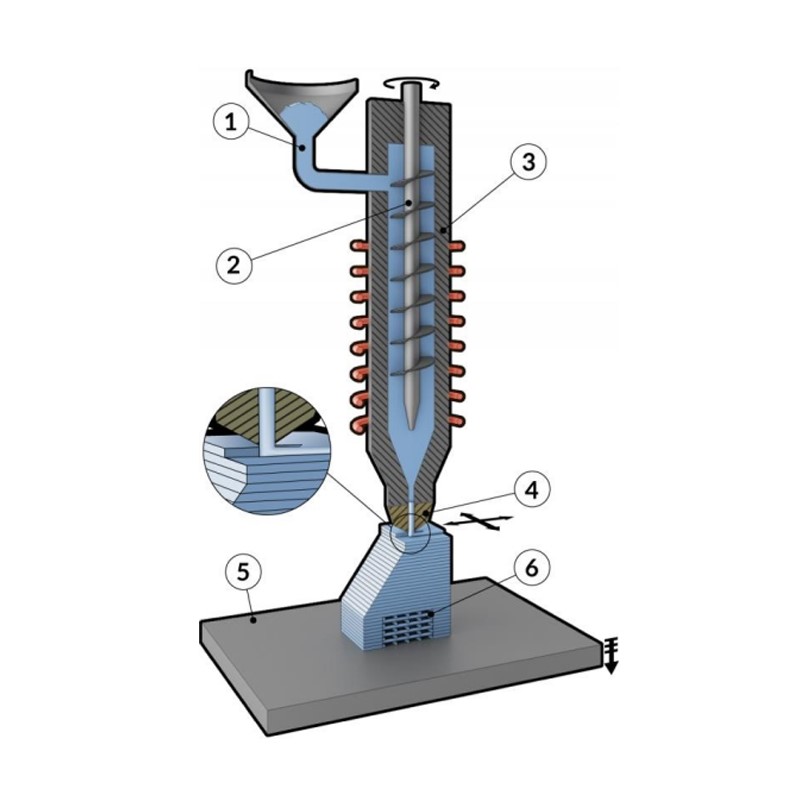

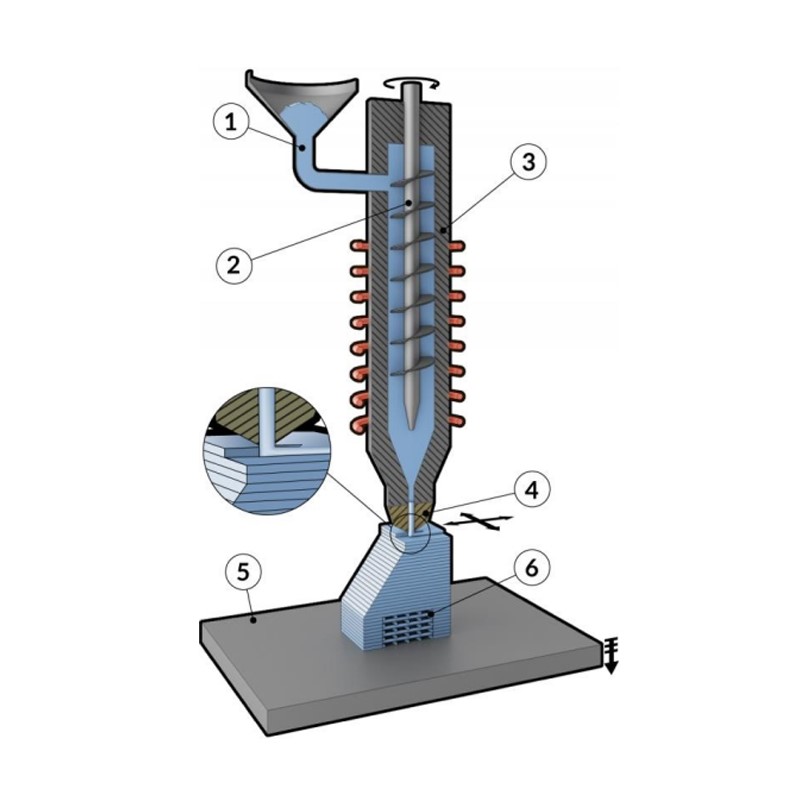

Like below picture shows:

FGF forms parts on a platform by melting granular pellets and expelling them through a nozzle. Granular pellets are fed into a hopper ① and gradually fed into a vertical extruder screw ② ③ which rotates, heats, and pushes the pellets down into a molten homogeneous plastic mass. The mass is compressed by a replaceable nozzle ④ whose flow rate is controlled by the diameter and shape of the channel.

Larger passes increase construction speed but reduce surface finish and vice versa. Material is deposited through the nozzle at a constant velocity, and a CAD model of the cross-section is built. After each layer, lower the construction platform ⑤ and add the next layer. If necessary, support structures ⑥ can also be printed for overhanging.

Finishing is required in the form of removal of these support structures.

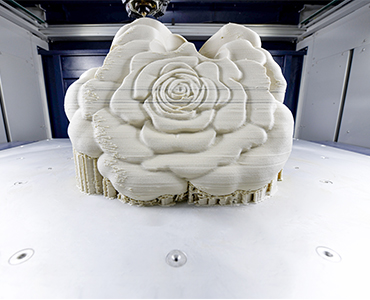

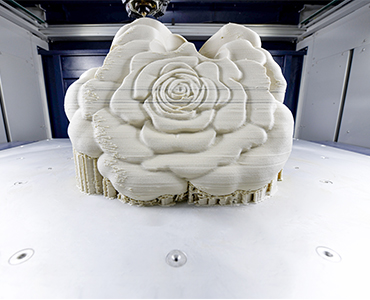

Due to the larger heating zone and wide-diameter nozzle of the pellet extruder, the material throughput may be tens of times or even nearly 100 times higher than that of FDM. FGF printers offer faster print speeds and higher throughput, a distinct advantage when printing large parts. Take Kings FGF printer as an example, with an extruder of a diameter of 12mm, the max print speed is 30kg/hour(based on stable printing speed 100mm/s)

The advantage of FGF using granular pallets is not only that granular pellets are far cheaper than filaments, but some materials cannot be made into filament due to their chemical properties, but they can be directly used by FGF. The most important thing is that FGF can use recycled materials, which is more environmentally friendly.

Besides, the principle of FGF printing is closer to injection molding, and its better mechanical properties are more suitable for the production of industrial parts than FDM printing. Like manufacturing of large tooling molds, direct and rapid manufacturing of composite parts, etc.

However, since its larger extruder, FGF 3D printing is more suitable for medium to large part sizes and not suitable for fine details or parts with complex geometries.

However, if you find you are limited by FDM's throughput, build envelope, or material cost, you will find FGF is a better option for you.

Contributor: Afrar/Yami