What is SLA 3D printing doing for the fashion industry?

——Practical Uses of industrial level SLA 3D Printers in Fashion

3D Printed Fashion Accessories

Instead of 3D printing full items of clothing, SLA 3D printers in fashion are used to supplement parts of a whole design, like embellishments, accessories, and buttons.

Using 3D printing, small end-use accessories can be easily assembled in minutes. 3D printing is also helpful when creating costume jewelry with complex geometries.

Prototyping and Tooling

Creating prototypes and tools for manufacturing are two of the most common uses of professional SLA 3D printers, and the fashion industry is no exception to this.

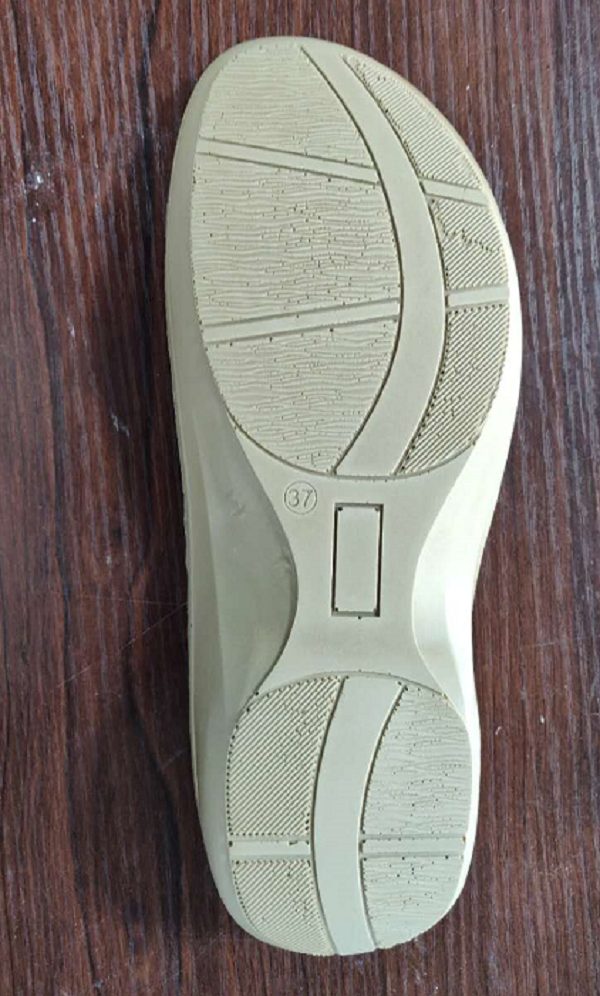

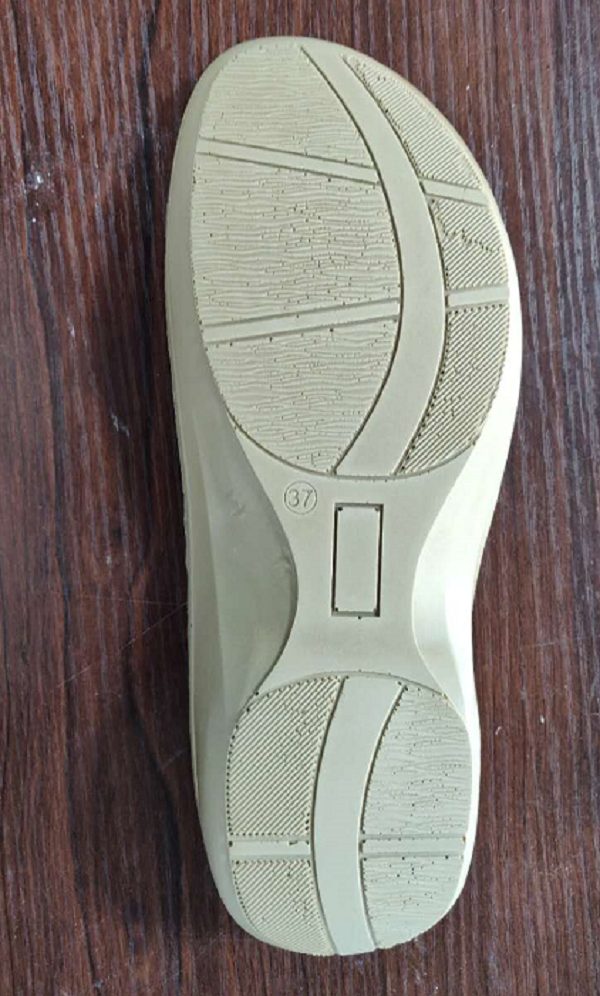

3D printing is changing the shoe industry. Previously, the shoe factories used to outsource the production of shoe models(prototypes) to check their designs, adding more costs and time to the overall design process. Now, with industrial SLA 3D printers in-house, their designers can get a much better understanding of the volumes and shapes of their designs. (See the below picture, Kings large-scale industrial SLA 3D printer Kings 6035Pro with 600*350*350mm printing size can print out 6 pairs of soles at a time.)

3D printers also encourage designers to take more design risks because they can quickly assess the viability of their designs. Prototyping different design iterations in this way gives designers more time and freedom to come up with new and innovative designs.

The 3D-printed mold skips the casting process and is directly used for the production of PU shoe soles. It can be used for plastic injection, PU, and cold-pressed insole molds. It is temporarily not suitable for hot-pressed rubber, molded EVA, and injection EVA.

Sustainability

3D printing in fashion is also gaining traction in sustainable fashion, as more designers and brands look for sustainable ways to produce their collections.

The innovative Spanish fashion brand ZER is a good example. They use additive manufacturing throughout their design and creation process as a way to be a sustainable force in the fashion industry.

They use a 3D printer to design a specific pattern and then only print as much as needed. This allows them to reduce resource waste per garment and ensure their manufacturing process is environmentally friendly.

3D printers benefit sustainable fashion efforts due to the reuse and recycling of materials to create new designs. It's also an effort that ZER is working on that could be interesting for a lot of different brands looking to step up their sustainability efforts.

Customization

Finally, 3D printing in fashion opens the door to new possibilities for customization options. Brands can start tailoring products to specific needs or body parts of consumers.

German sportswear company Adidas has been experimenting with the concept since 2015. Using data from athletes' runs, they created a shoe that fits any runner. Today, they continue to experiment with different versions of the 3D printed shoe.

Conclusion

All in all, from end-use design to behind-the-scenes processes, 3D printing is establishing its place and dominance in the fashion industry. It will be exciting to watch the innovations, tactics, and designs created as this technology evolves.

you can learn more about Kings 3D and SLA technologies.

1. Brief Introduction to Kings 3D:

https://www.youtube.com/watch?v=ELJbyrH0Nqo

2. Key Components of Kings 3D Printers:

https://www.youtube.com/watch?v=z60BmjhalFY

3. Operating Progress and Main Specifications of Kings 3D Printer:

https://www.youtube.com/watch?v=aEEhoKmT-8U

4. Customer case by applying 3d printer in shoe design and mold:

https://www.youtube.com/watch?v=kzpqz2V55SU&t=3s

Author: Gary / Lili Lu / Seazon