What is the workflow of FGF 3D printing?

Fused Granular Fabrication, FGF, is an additive manufacturing method using plastic granules (pellets) as consumables to feed into a nozzle and build the 3D object on a bed layer by layer.

It is also known as pellet extrusion printing, pellet printing, fused pellet fabrication, or fused particle fabrication.

It is widely used for sculpture making, furniture designing, the toy industry, art crafts, mold manufacturing, plaques, landscape signs, etc.

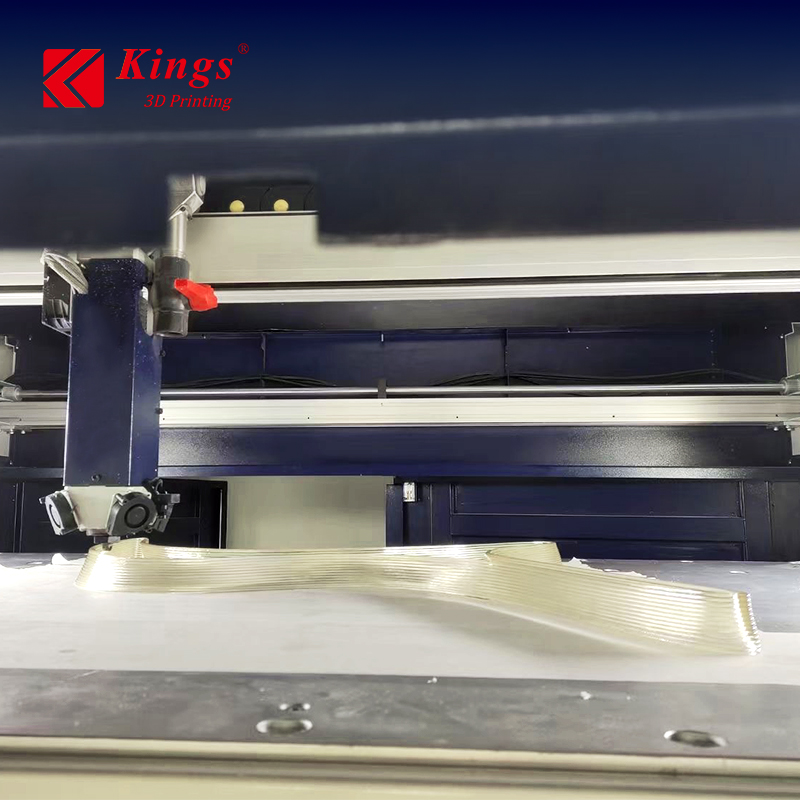

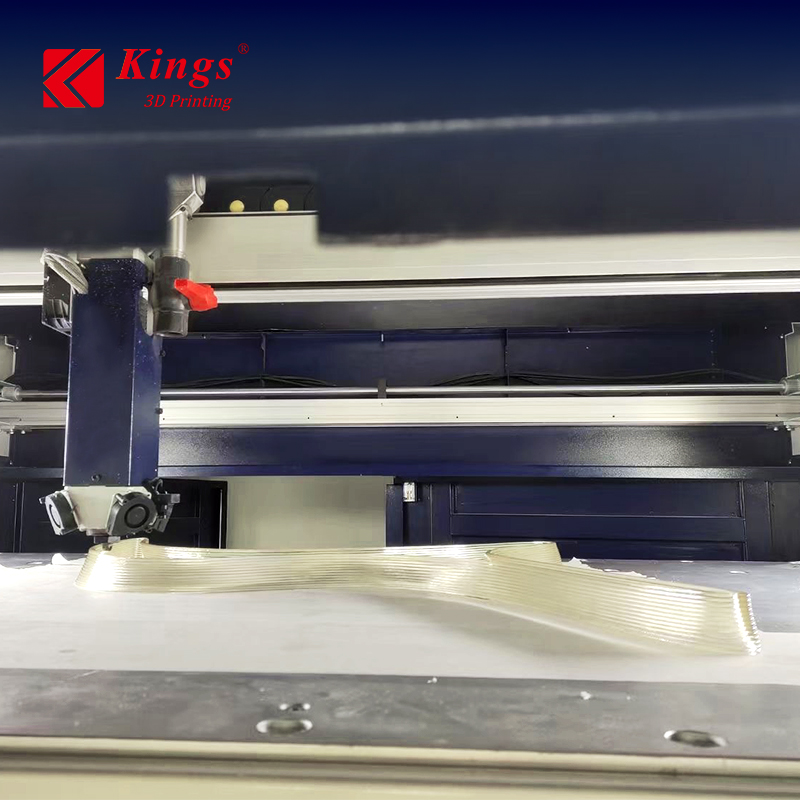

▲ Printing Chamber of FGF1800 3D Printer

Here I would like to give a brief introduction to the workflow of Kings FGF 3D printers.

Before feeding the granules into the printer supply chamber, the plastic granules are needed to dry in a drying machine.

If there is too much moisture in the plastic pellets, it will affect the printing quality.

Dry plastic granules are supplied to a funnel and conveyed to an extrusion screw.

In this extrusion screw, pellets are heated and melted, then pressed through a nozzle to form a 3D object layer by layer according to the preset layer thickness in 3D printing software.

The printing platform will move down vertically by layer until the printing is finished.

▲ Kings FGF1800 pellet printer with a max build size 1800*1300*1300mm

The post-processing of FGF printed models includes support removing, sticking pieces together with welding nails if required, grinding and sanding, and surface treatment like painting.

After surface finishing, the pellet print models can used for display and indoor and outdoor decorations.

▲ Kings FGF 3D Printed Effect Appreciation

If you want to know more information about Kings FGF 3D Printer, Welcome to Contact Kings Professional Sales.

Contributor: Grace / Lili Lu / Seazon