Keywords: 3D Printing Technology, Kings 3D Printers, Shoe Mold Manufacturing Industries, SLA Technology In the Footwear Industry, Kings SLA 3D Printer, Kings Resin Material

In recent years, 3D printing technology has rapidly evolved and it has made its way into various industries, including the shoe mold manufacturing industry. More and more shoe mold manufacturing industries worldwide are adopting 3D printing technology to create highly customized and efficient production processes.

The footwear industry is one of the largest and fastest-growing industries in the world. According to Statista, the global footwear market was valued at approximately $343 billion in 2020 and is expected to reach approximately $508.2 billion by 2027. Shoe molds are the basic tool for producing shoes and play an important role in the shoe manufacturing process. As the demand for footwear continues to rise, so does the demand for shoe molds.

3D printing technology application advantages:

Conventional shoe molds are manufactured using a subtractive manufacturing process in which a block of metal is cut and shaped into the desired mold using a CNC machine. This process is time-consuming, and expensive, and allows for limited design possibilities. SLA 3D printing technology, on the other hand, enables shoe mold makers to produce molds with complex geometries, customized designs, and improved accuracy. There are several advantages to using 3D printing in shoe mold manufacturing compared to traditional methods.

SLA 3D rapid printing technology allows for the creation of molds with intricate details and shapes.

This was previously unattainable. This allows designers to create molds that are more comfortable and more aesthetically pleasing to the wearer.

3D printing has greatly reduced the time and cost of producing shoe molds.

Traditional manufacturing methods require the use of expensive machinery and skilled labor, which increases production costs. In contrast, 3D printing eliminates the need for specialized molds and reduces the time required for production, resulting in cost savings for manufacturers.

SLA 3D printing technology also improves precision and accuracy in the manufacturing process.

This is particularly important in shoe mold production, as even small deviations in size and shape can result in ill-fitting shoes.

Some well-known footwear manufacturers, such as Adidas, have successfully used 3D printing technology to produce shoe molds, and it is not difficult to predict that soon, 3D printing will become a must-have production condition for the shoe mold manufacturing industry.

KS908C is a brown color SLA resin which widely used in the shoe mold industry due to its fine surface textures, temperature resistance as well and good strength.

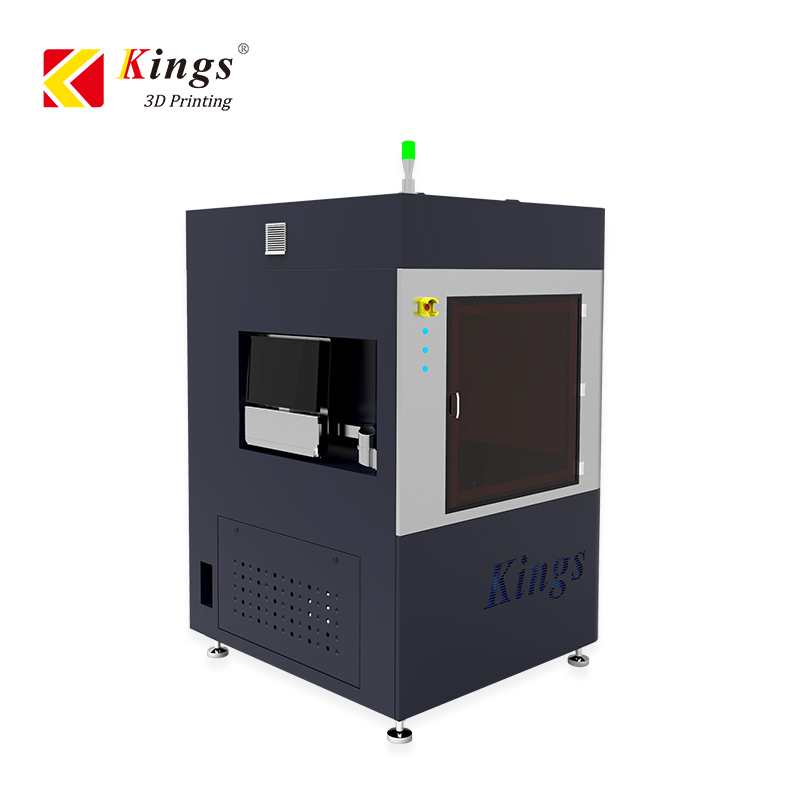

Kings 6035 Pro and Kings 600 Pro are very popular among our customers in the field of shoe mold industry.

Kings 600 pro SLA 3D Printer

Kings 6035 pro SLA 3D Printer

If you are interested in this article or want more information, please contact us here.

Author: Harry/Lili Lu/Christine