KS-TPU-23

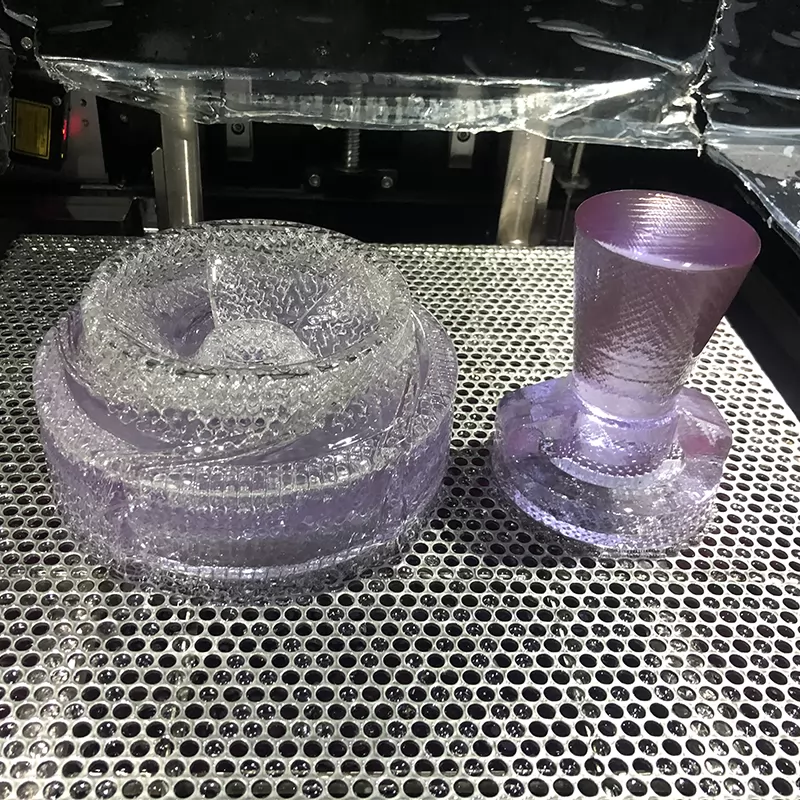

Thermoplastic polyurethane (TPU), a member of the thermoplastic elastomer (TPE) family, combines the elasticity of rubber with the strength of plastic. Chemically, TPU is a block copolymer consisting of alternating hard segments (isocyanates) and soft segments (reacted polyol), and the manufacturer determines their ratio. More soft segments enhance flexibility, leading to a shore hardness ranging from 60A (similar to mild silicones) to 80D (comparable to nylons or rigid PVC). TPU is versatile, and available in various forms tailored to different manufacturing technologies, including filament for FDM and powder for SLS in 3D printing.

TECHNICAL DATASHEET

PRODUCT DESCRIPTION

Thermoplastic polyurethane (TPU), a member of the thermoplastic elastomer (TPE) family, combines the elasticity of rubber with the strength of plastic. Chemically, TPU is a block copolymer consisting of alternating hard segments (isocyanates) and soft segments (reacted polyol), and the manufacturer determines their ratio. More soft segments enhance flexibility, leading to a shore hardness ranging from 60A (similar to mild silicones) to 80D (comparable to nylons or rigid PVC). TPU is versatile, and available in various forms tailored to different manufacturing technologies, including filament for FDM and powder for SLS in 3D printing.

TYPICAL FEATURES

> Elasticity

> High elongation and tensile strength

> Low-temperature performance

> Abrasion resistance

> Chemical resistance

IDEAL APPLICATIONS

- Shock-absorbing shoe soles

- Insoles

- Medical organ models

- Flexible robots

- Smart wearable devices

- Biological scaffolds

- Lining for apparel prosthetic

TECHNICAL DATASHEET

| Performance | Testing methods | Units | Typical values |

| Bulk density | GB/T 16913 | g/m³ | 0.5 |

| Powder color | Visual inspection |

| White |

| Part color | Visual inspection |

| Natural color |

| Shore hardness A | ISO 868 | ℃ | 88-90 |

| Tensile strength | DIN 53504 | MPa | 20 |

| Elongation at break | DIN 53504 | MPa | 400 |

| Melting point | ISO 11357 | ℃ | 160 |

Note:

1. The above parameters are limited to the calibrated testing method, and the test reading results of samples produced with different heat parameters may vary.

2. Due to measurement errors in different testing equipment, a deviation of up to 15% from the above values in both directions can be considered as consistent results.