- Home

-

Products

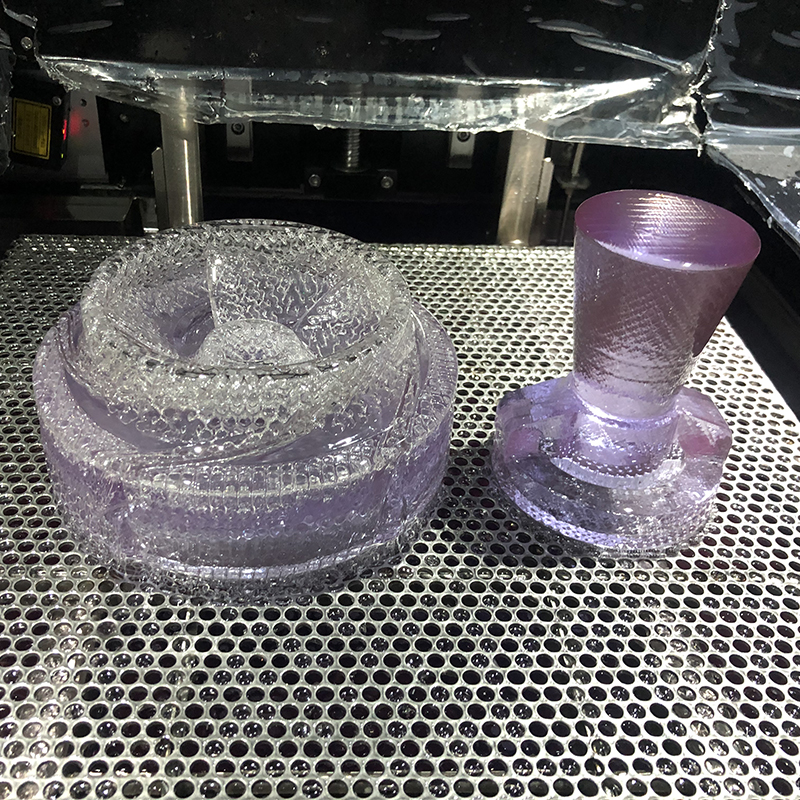

- SLA 3D Printer

- Kings SLA 400 3D Printer

- Kings 2700Pro SLA 3D Printer

- KINGS 3035Pro SLA 3D Printer

- KINGS 450Pro Industrial SLA 3D Printer

- KINGS 6035Pro Industrial SLA 3D Printer

- KINGS 600Pro Industrial SLA 3D Printer

- KINGS 650Pro Industrial SLA 3D Printer

- KINGS 800Pro Industrial SLA 3D Printer

- KINGS 850Pro Large Print Volume SLA 3D Printer

- Kings SLA 1000pro 3D Printer

- KINGS 1200Pro Industrial SLA 3D Printer

- KINGS 1450Pro Industrial SLA 3D Printer

- Kings SLA 1700 Pro 3D Printer

-

3D Printer by Industry

- KINGS 800Pro Large Prototype Printer

- KINGS1700 Pro SLA 3D Printer

- Kings 1700 Large-Size High-Speed 3D Printer for Automobile Modeling

- KINGS 600Pro Rapid Prototyping 3D Printer

- KINGS 600Pro Shoe Model Printer

- KINGS 6035Pro Footwear 3D Printer

- KINGS 800Pro Automotive 3D Printer

- KINGS 1700Pro Car 3D Printer

- KINGS 800Pro Architecture 3D Printer

- KINGS 800Pro Sculpture 3D Printer

- KINGS 600Pro Medical 3D printer

- KINGS 600Pro Art&Craft 3D Printer

- KINGS 600Pro Quick Casting 3D Printer

- SLM 3D Printer

- SLS 3D Printer

- FGF 3D Printer

- FDM 3D Printer

-

Material

- UV Resin KS168C

- UV Resin KS198S

- UV Resin KS908C

- UV Resin KS408A

- UV Resin KS608A

- UV Resin KS158T

- SLM Material CoCr

- SLM Aluminum Alloy

- SLM Nickel Based Alloy In 718

- SLM Material Stainless Steel 316L

- SLM Material Copper-tin Alloy CuSn10

- Nylon Powder KSPA12

- Nylon Powder KSPA12GB

- Nylon Powder KSPA12BK

- KS-TPU-23

- UV Resin KS808-BK

- SLA 3D Printer

- Applications

- News

- About Us

- Contact Us