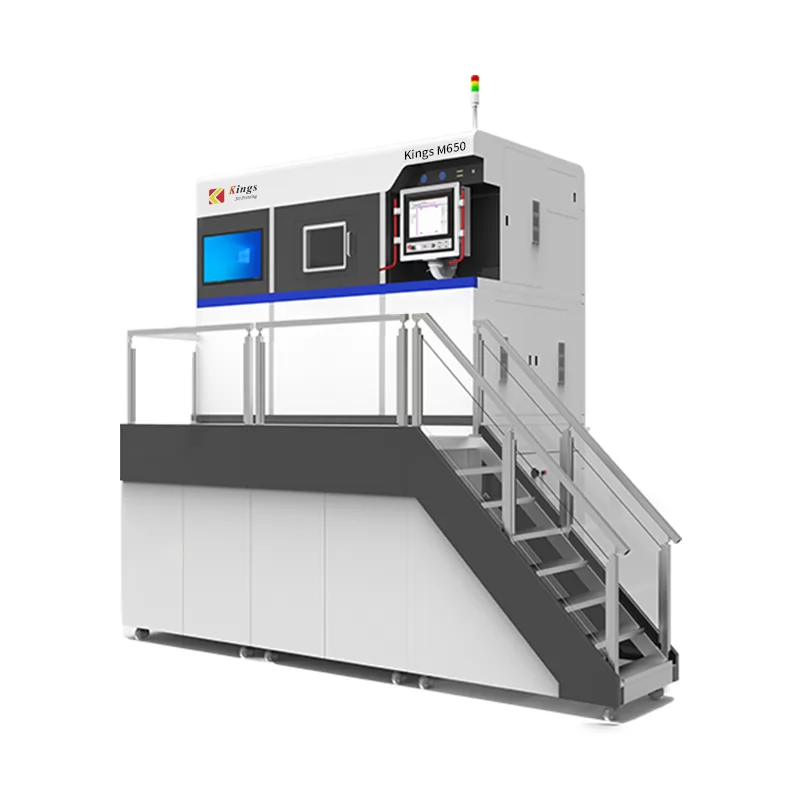

Overview

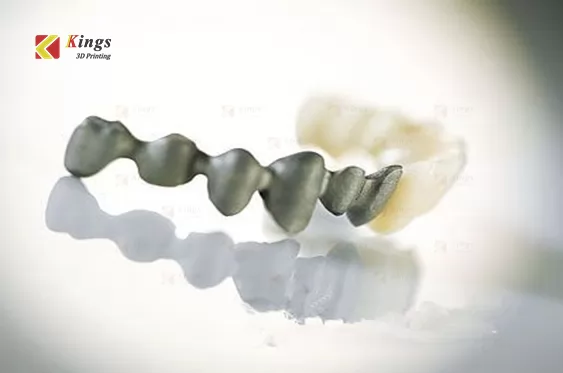

Kings M100E has an exquisite shape design with a upgraded build cylinder, high precision and high efficiency, and it can process and produce a variety of materials. Mainly used in the R&D and production of small precision parts in dentistry, orthopedics jewelry, scientific research and education.

Advantage

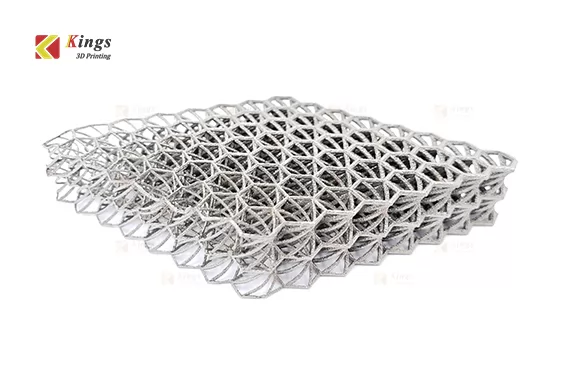

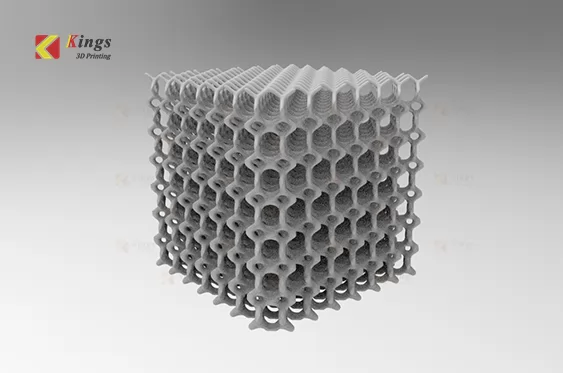

(1) High Precision & High Quality

Supports 20μm laser spot size. Precisely print out every structural detail, Adopting a concentrated laser, the energy greatly enhances the density and strength of the printed part.

(2) All Closed Looped Powder Handling System

The low oxygen content in the manufacturing environment ensures that the metal is not oxidized, and is compatible with powders of different specifications.

(3) Double Circulation Wind Site Protection System

Dual-circulation wind site protection system to extend the lifespan of the optical components.

(4) Fully Pop-up Piston System

Equipped with a fully pop-up piston system, it is more convenient and quicker to replace metal powders, and 100% eliminates cross powder contamination when replacing powders.

ldeal Applications

R&D and production of small precision parts for dentistry, orthopedics, jewelry,etc.;research education, etc.

Basic Parameter